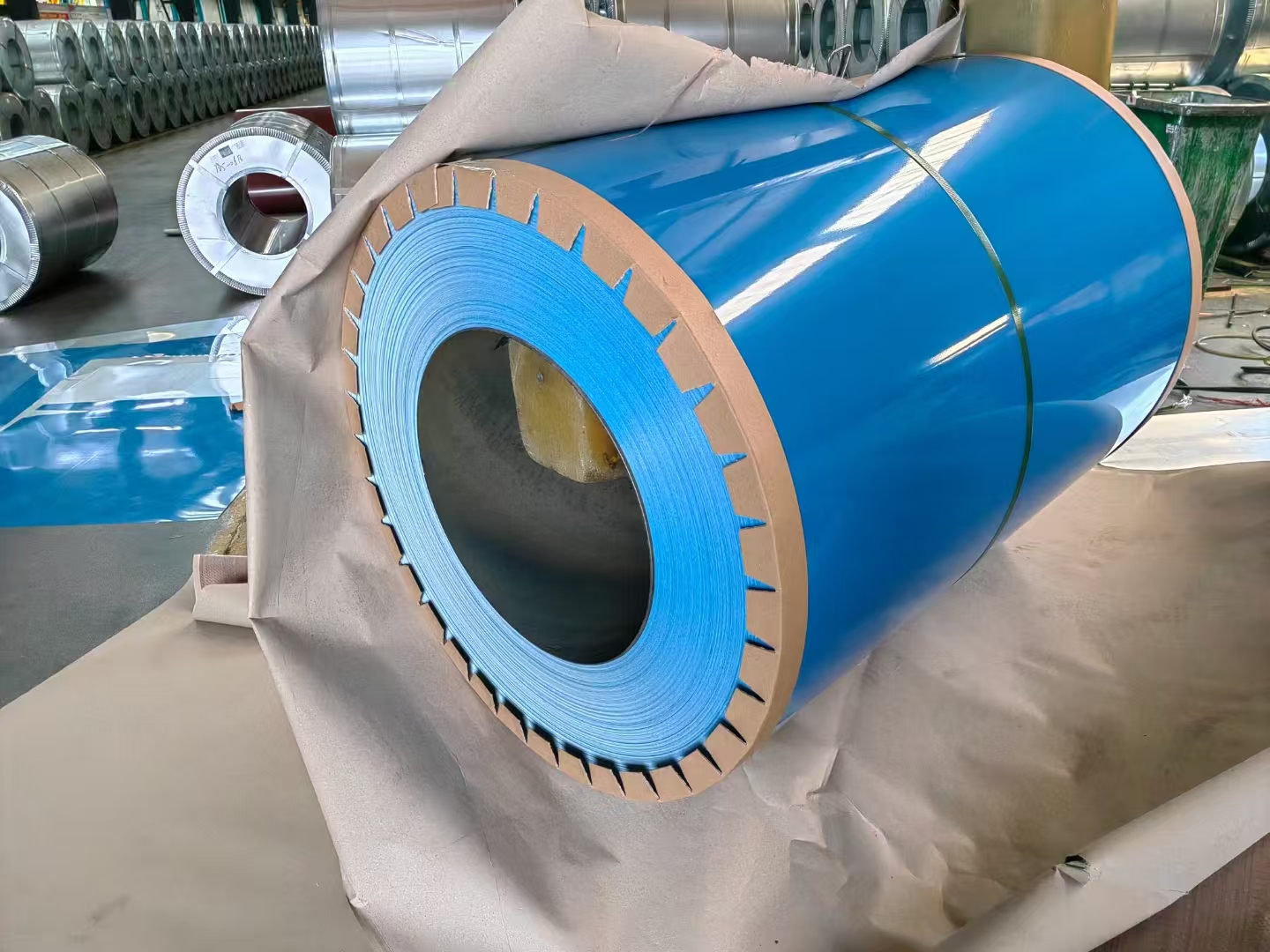

Definition and Structure

Pre-coated steel coils are manufactured using cold-rolled steel sheets, galvanized steel sheets, or other similar substrates. After surface pretreatment (degreasing, cleaning, and chemical conversion), they are coated with one or more layers of organic coatings via a continuous roller coating process and finally cured by baking. Their structure includes a substrate, an optional coating, a chemical conversion layer, and the coating.

Substrate Classifications

Hot-dip galvanized steel sheets are dipped into a bath of molten zinc, resulting in a layer of zinc adhering to the surface. In addition to the protective properties of zinc, the organic coating on the surface of hot-dip galvanized pre-coated steel sheets also provides insulation and rust resistance, resulting in a longer service life than hot-dip galvanized steel sheets. Their zinc content is typically 180g/m² (both sides).

Hot-dip galvanized steel sheets (55% Al-Zn) are used as the substrate, typically with an Al-Zn content of 150g/m² (both sides). Hot-dip galvanized steel sheets have corrosion resistance 2-5 times greater than hot-dip galvanized steel sheets. They withstand continuous or intermittent use at temperatures up to 490°C without significant oxidation or scale formation.

Electrogalvanized substrate: Electrogalvanized steel sheets are coated with an organic coating and then baked. Due to the thin zinc layer, typically containing 20/20 g/m², electrogalvanized steel sheets are not suitable for outdoor applications such as walls and roofs. They are primarily used in home appliances, audio equipment, steel furniture, and interior decoration.

Coating Structure

2/1: Coat the top surface twice, coat the bottom surface once, and bake twice. A single coat of backside coating has poor corrosion and scratch resistance, but exhibits good adhesion and is primarily used in sandwich panels.

2/1M: Coat the top and bottom surfaces twice, bake once. This backside coating offers excellent corrosion resistance, scratch resistance, formability, and adhesion, making it suitable for single-layer profiled panels and sandwich panels. 2/2: Coat the top and bottom surfaces twice, then bake twice. Double-layer backside coating offers excellent corrosion resistance, scratch resistance, and formability, and is primarily used for single-layer profiled panels. However, its poor adhesion makes it unsuitable for sandwich panels.

Coating Types

Ordinary Polyester (PE): Offers excellent adhesion, a variety of colors, easy formability, and low cost. Under normal conditions, it has a service life of 7-10 years and is suitable for areas with moderate air pollution.

Silicon-Modified Polyester (SMP): Utilizes a special silicone resin to enhance the coating's abrasion resistance and metal scratch resistance, making the coating harder, durable, and resistant to chalking. It offers a moderate cost. Under normal conditions, it has a service life of 12-15 years and is primarily used for roofs and exterior walls.

High Durability Polyester (HDP): A high molecular weight polymer composed of a special polyacid and polyol. It is almost completely transparent to UV rays, improving the coating's gloss retention and chalking resistance. It is also resistant to photolysis, offers excellent film adhesion, and offers a high cost-effectiveness. Under normal conditions, it has a service life of over 15 years. Polyvinylidene fluoride (PVDF): The finest architectural coating available, it offers exceptional stability, unique resistance to UV degradation and chemical degradation, as well as excellent insulation and mechanical properties. It boasts a guaranteed service life of over 20 years.

Main Applications

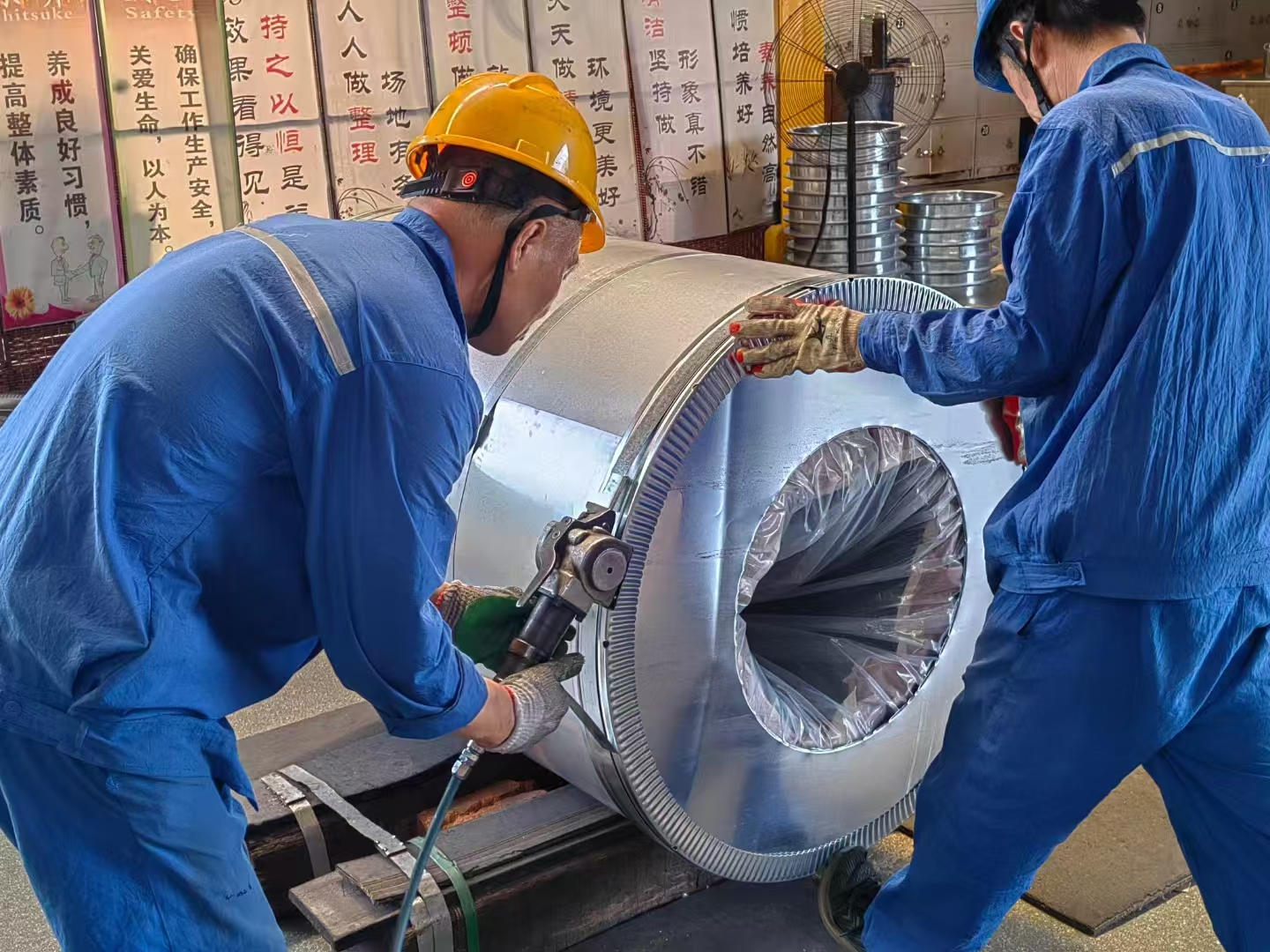

Color-coated coils are lightweight, aesthetically pleasing, offer excellent corrosion resistance, and are readily processable. Available in off-white, ocean blue, and brick red, they are primarily used in advertising, construction, home appliances, furniture, and transportation.