Polyurethane insulated pipe, also known as high-density polyethylene outer protective pipe with rigid polyurethane foam prefabricated direct-buried insulated pipe, is a highly efficient insulated pipeline widely used for various fluid transportation applications. Here is a detailed introduction:

Structural Composition

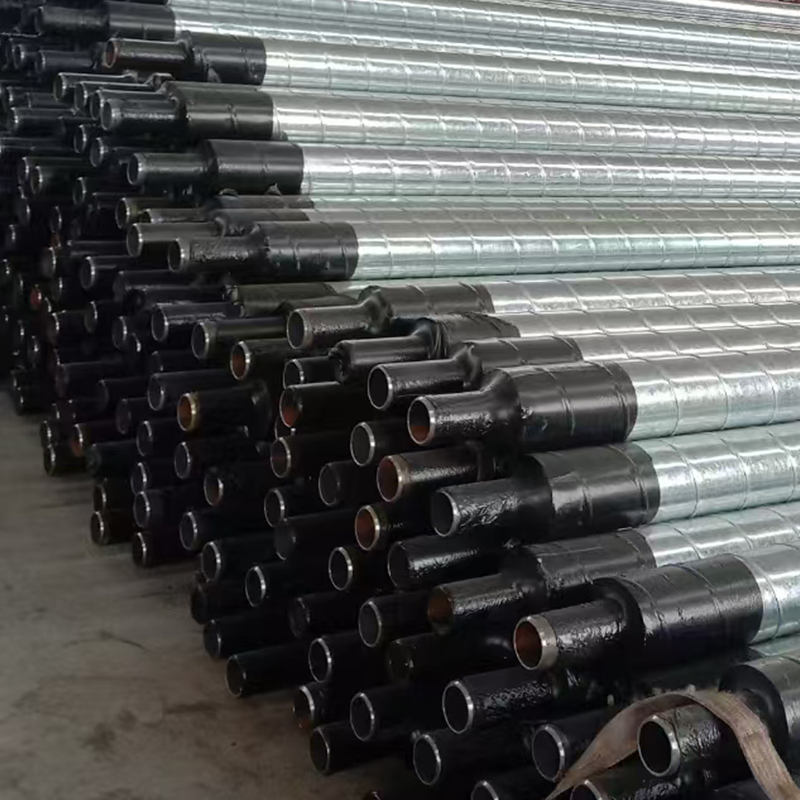

**Working Steel Pipe Layer:** Located at the innermost layer, it is generally made of seamless steel pipe, spiral welded pipe, or straight seam welded pipe. The steel pipe surface usually requires shot blasting to remove rust, achieving a rust removal grade of Sa2.5, to enhance adhesion to the insulation layer.

Building Materials: Seamless steel pipe

Polyurethane Insulation Layer: Rigid polyurethane foam is injected into the cavity between the steel pipe and the outer protective pipe using a high-pressure foaming machine, forming the insulation layer through a "pipe-in-pipe foaming process." It features low thermal conductivity and waterproofing, effectively reducing heat loss and supporting the weight of the heating network.

Chemical Raw Materials:Rigid polyurethane foam

High-Density Polyethylene Protective Layer: As the outermost layer, it is prefabricated into a black or yellow plastic pipe of a certain wall thickness. It protects the polyurethane insulation layer from mechanical damage and provides good corrosion and waterproof performance.

Chemical Raw Materials: Rigid polyurethane foam

High-Density Polyethylene Protective Layer: As the outermost layer, it is prefabricated into a black or yellow plastic pipe of a certain wall thickness. It protects the polyurethane insulation layer from mechanical damage and also provides good corrosion and waterproofing properties. Building Materials: High-Density Polyethylene Pipes

Performance Characteristics

Excellent Thermal Insulation: Low thermal conductivity, approximately 0.013-0.03 kcal/m·h·℃, providing 4-9 times better insulation than traditional insulation materials. Heat loss in the heating network can be controlled within 2%.

Good Corrosion Resistance and Insulation: The polyurethane insulation layer is tightly bonded to the outer skin of the steel pipe, preventing air and water penetration. The high-density polyethylene outer protective pipe also has excellent corrosion resistance and insulation properties, extending the pipeline's service life to over 50 years.

Convenient Construction: No need for pipe trenches; it can be directly buried underground or underwater, reducing earthwork excavation and civil engineering work. Construction is fast, shortening the construction period by approximately 50%.

Cost Savings: Although the pipe material itself is relatively expensive, the overall cost is lower due to the reduction in earthwork and masonry costs, generally reducing project costs by 10%-25%. Application Areas:

Urban Central Heating: Used in urban heating networks to effectively prevent heat loss and ensure residents' heating needs are met.

Industrial Sector: In industries such as petroleum, chemical, and pharmaceutical, it can be used to transport high-temperature media such as hot oil and steam, achieving heat preservation and energy-saving effects.

Building Sector: Suitable for heating, cooling, and hot water supply systems in large public buildings and residences.

Municipal Engineering: Applicable to urban heating networks, gas pipelines, sewage treatment, and other municipal infrastructure.