-80px

-80px

-80px

-80px

Product Description

Superior Corrosion Resistance: Adopts the hot-dipped galvanizing (HDG) process — the steel pipe is fully immersed in molten zinc, forming a dense, uniform zinc coating (coating thickness usually meets ASTM A123 or EN ISO 1461 standards) on both internal and external surfaces. This coating acts as a robust barrier against moisture, chemicals, salt spray, and harsh environmental factors, significantly extending the product’s service life (service life can reach 20-50 years in different environments, far longer than ordinary painted steel pipes).

High Structural Strength: Made of high-quality carbon steel (e.g., Q235, S235JR, or A36, depending on specific grades), the square hollow structure combines light weight with excellent load-bearing capacity, bending resistance, and torsion resistance. It can withstand heavy static loads and moderate dynamic loads, making it suitable for structural support scenarios.

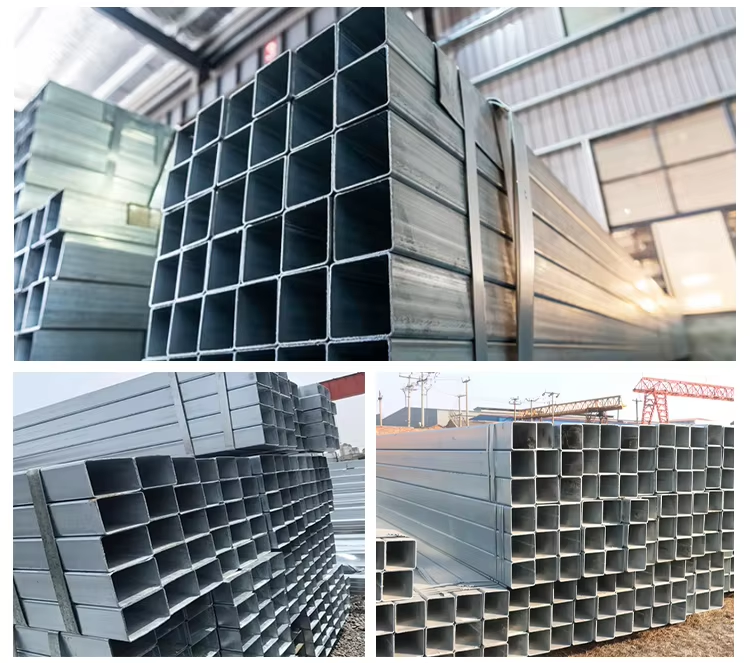

Smooth & Uniform Surface: After hot-dipped galvanizing, the pipe surface presents a consistent silver-gray metallic luster, with no obvious burrs, pits, or coating defects. The smooth surface not only enhances aesthetic appeal but also facilitates subsequent processing (such as cutting, drilling, welding) and reduces friction during installation.

Excellent Processability: The square hollow design and galvanized coating maintain good weldability (compatible with common welding methods like MIG, TIG, and arc welding) and machinability. It can be easily cut to custom lengths, punched for mounting holes, or bent into specific shapes without damaging the galvanized coating (with proper processing techniques).

Cost-Effective Durability: Although the initial cost is slightly higher than that of ungalvanized or painted steel pipes, the long service life, minimal maintenance requirements (no frequent repainting or anti-corrosion treatments), and low replacement frequency make it a cost-effective choice in the long run.

Compliance with Standards: Manufactured in accordance with international quality standards (such as ASTM A500 for steel hollow sections, ASTM A123 for galvanizing, or EN 10219), ensuring stable product performance, consistent dimensions, and reliable quality for global market applications.

Application

Structural engineering (buildings, bridges, towers)

Machinery manufacturing

Steel frameworks and fabrication

Transportation equipment

Furniture and architectural projects

Fencing, gates, and support columns

Certifications

FAQ

Q: What materials are used to manufacture rectangular steel pipes?

Q: What are the common manufacturing standards?

Q:What surface finishes are available?

Q: How are rectangular steel pipes packaged for shipping?