-80px

-80px

-80px

-80px

Product Description

Specification

| item | value |

| Grade | 304, 310,316L, 316, 314, 430, 409L, 304L |

| Standard | ASTM |

| Tolerance | ±1% |

| Surface Finish | BA |

| Place of Origin | China |

| Delivery Time | 15-21 days |

| Diameter | 4-800mm or Customized |

| Length | 1-12m or Customized |

| Brand Name | ZCXH |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting |

| Product name | Stainless Steel Round pipe |

| Technique | Cold Rolled Hot Rolled |

| Shape | Round |

| Keyword | Staninless Steel Round Pipe |

| Type | Round pipe |

| Material | 201/202/309/309S/310/310S/304/304L/316/316L/316Ti/321 |

| MOQ | 1 Tons |

| Packing | Standard Sea-worthy Packing |

| Payment term | 30%T/T Advance + 70% Balance |

| Sample | Provided |

Products Application

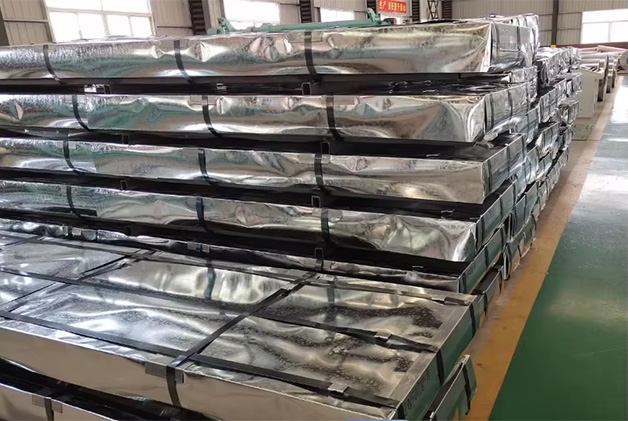

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.