-80px

-80px

-80px

-80px

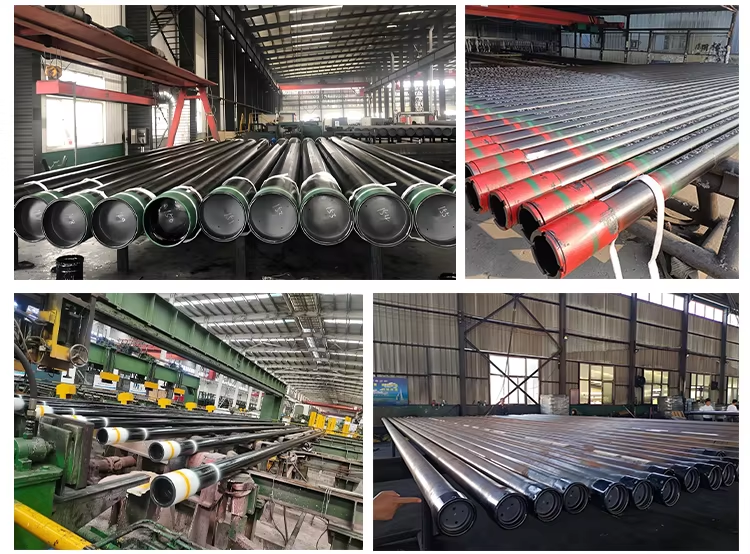

Production Process

Product Description

✅ High-strength steel, suitable for complex well conditions

The oil casing is made of high-strength alloy steel (such as N80, P110, Q125, etc.), which has excellent tensile, compressive and bending resistance. It can withstand extreme working conditions such as deep Wells, high pressure and high temperature, effectively preventing wellbore collapse or pipe body rupture.

✅ Excellent connection and sealing performance

Equipped with API standard threads (such as STC, LC, BC) or advanced gas-tight connections (such as VAM, Hydril, etc.), it can provide excellent sealing performance, effectively preventing gas leakage and blowout accidents, and is particularly suitable for high-pressure gas Wells or H₂S environments.

✅ Multi-layer anti-corrosion process extends service life

Depending on the different corrosion environments of the strata, various surface treatment methods such as phosphating treatment, copper coating, epoxy powder coating or external anti-corrosion coating can be selected, effectively enhancing the resistance to sulfur, CO₂ and chloride ion corrosion.

✅ It is adaptable to various well types and highly flexible

It supports the structural design of various well types such as conventional vertical Wells, directional Wells, horizontal Wells, deep Wells, and ultra-deep Wells, and can be matched with various wellbore structure combinations to enhance the efficiency and success rate of oilfield operations.

Product Paramenters

| All specifications products can be customized according to customer requirements | |

| Product name | Seamless Oil Pipe |

| Process | Hot rolled and cold drawn |

| Standard | API 5L, API 5CT, ASTM A106/A53, ASTM A519, JIS G 3441, JIS G3444, JIS G3445 DIN 2391, EN10305, EN10210, ASME SA106, SA192, SA210,SA213, SA335, DIN17175, ASTM A179 |

| Our diameter | 1/8 – 30 inch (10.3-762mm) |

| Wall Thickness | 1.24mm- 63.5mm |

| Length | Random Length, Fixed Length, SRL, DRL |

| Steel Grade | API 5L: GR B, X42, X46, X56, X60, X65, X70 ASTM A53/A106: GR A, GR B, GR C ASME SA106: GR.A, GR.B, GR.C ASME SA192: SA192 ASME SA209M: T1, T1a ASME SA210: GR.A-1, GR.C ASME SA213: T2, T5, T9, T11, T12, T22 ASME SA335: P2, P5, P9, P11, P12, P22, P91 DIN17175:ST35.8, ST45.8, 15Mo3, 13CrMo44 |

| Surface | Fusion Bond Epoxy Coating,Coal Tar Epoxy,3PE,FBE,Varnish coating,Bitumen coating,Black Oil coating as per customers requirement |

| Treatment | Heat treatment:Annealed: Bright annealed,Spheroidize annealed, Normalized, Stress relieved, Cold finished, Quenched and Tempered. |

| Application | Applicable to the general structure, mechanical structure, water wall panel, economizer, super heater, boiler and heat exchanger with seamless steel tubes, and to transport liquid, gas, oil etc. |

Company Information

Shandong Zechen Xinghua New Materials Co., Ltd. is a manufacture integrating production and trade, with more than 30 years of experience in high-quality production, providing one-stop service for global customers. The company specializes in the production and sales of Carbon steel pipe/bar/plate/coil/, Galvanized steel plate/coil, Stainless steel pipe/plate/coil/bar,Section steel(H-beams/T-beams/Chan-nel steels/Angle steels/Cross steels/Etc.) Rebar/Deformed steel bars,Aluminum plate/coil/pipe/bar,Copper/Brass/Bronze/Copper alloy and other metal products. Among them, our precision seamless steel pipes and welded steel pipes ofvarious diameters have reached the world's leading level, with an annual export volume of over 100,000 tons.Products are exported to Europe, the Middle East, Southeast Asia, Australia, Latin America South Africa and other more than 60 countries and regions.We have won the recognition of customers with good reputation and good service.

Packing & Delivery

Application

Development of onshore and offshore oil and gas Wells. Shale gas and coalbed methane drilling projects. Complex drilling projects such as deep Wells, ultra-deep Wells and horizontal Wells.

Certifications

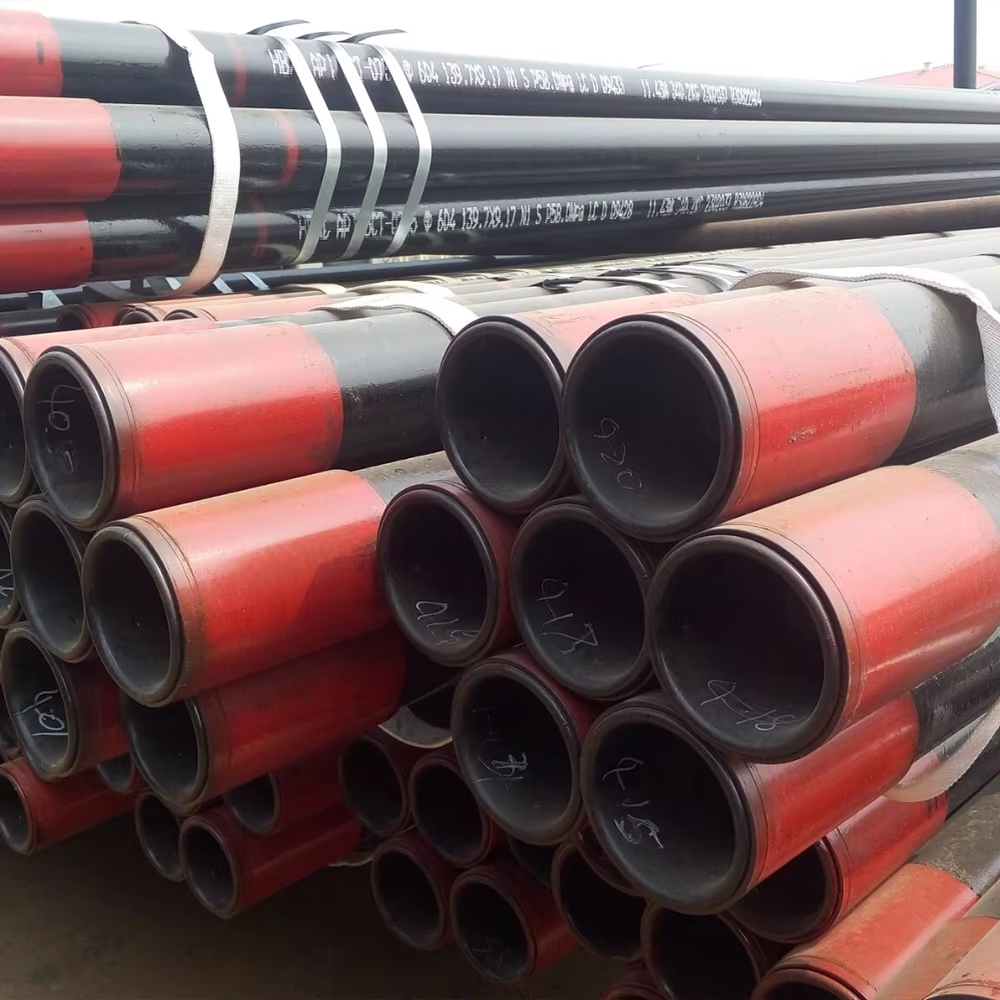

Customer Photos

FAQ

Q: What types of oil casing are there? How to choose?

A:It is mainly divided into the following categories: Surface casing: Isolates the shallow water layer to prevent pollution. Technical casing (Intermediate casing) : Sealing unstable strata. Production casing: It runs through oil and gas layers for long-term exploitation. Selection basis: well depth, pressure, formation characteristics and operation requirements.

Q: What are the commonly used steel grades (steel material grades)? What are their respective characteristics?

Q:What surface treatments are needed for the casing?

Q: Can oil casing be used in acidic gas (H₂S/CO₂) environments?