-80px

-80px

-80px

-80px

Production Process

Product Description

API 5L X52 steel pipe is a high-performance, seamless or welded (ERW/SAW) steel pipe compliant with API Specification 5L—a flagship grade in the API 5L series, specifically engineered for oil, gas, and hydrocarbon transmission. As a high-strength low-alloy (HSLA) steel grade, it balances exceptional mechanical strength, ductility, and corrosion resistance, making it a top choice for onshore/offshore pipelines, gas distribution mains, and oilfield flowlines. Its core features are detailed below:

Packing & Delivery

Application

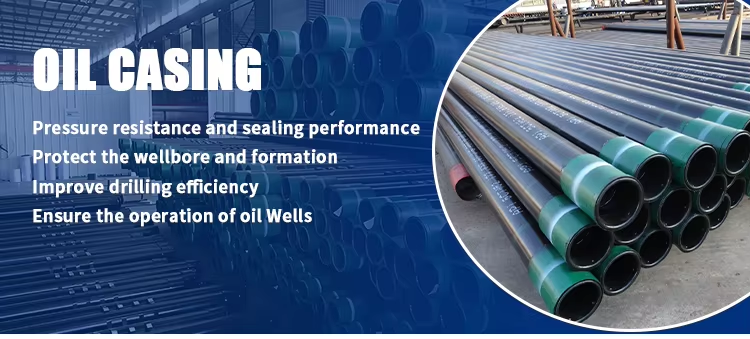

Development of onshore and offshore oil and gas Wells. Shale gas and coalbed methane drilling projects. Complex drilling projects such as deep Wells, ultra-deep Wells and horizontal Wells.

Certifications