-80px

-80px

-80px

-80px

Product Description

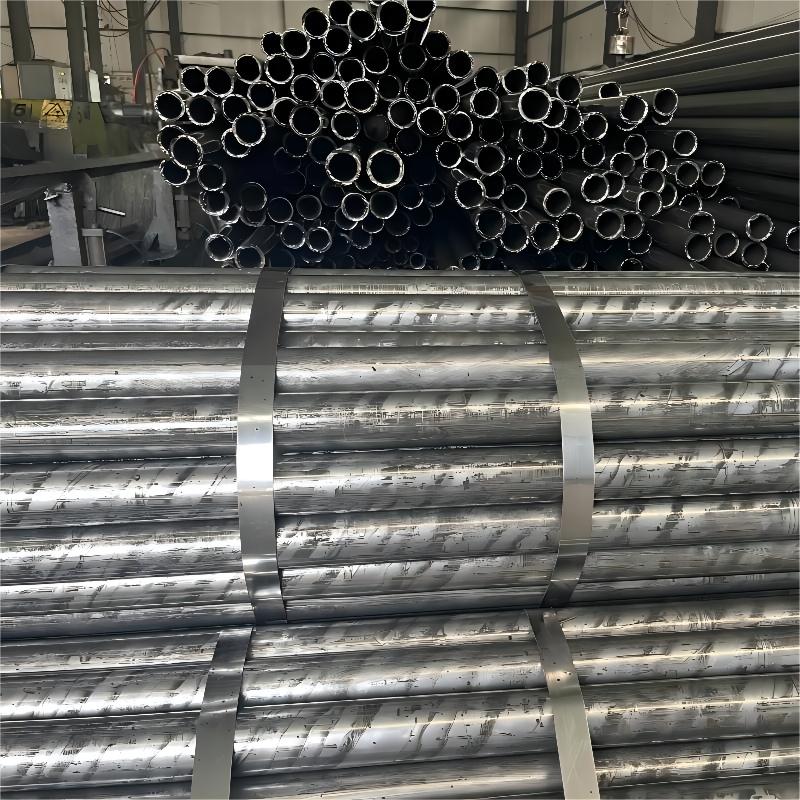

ASTM A106 and ASTM A53 are two distinct seamless steel pipe standards, each optimized for specific industrial scenarios. ASTM A106 seamless pipes are primarily designed for high-temperature and high-pressure service, while ASTM A53 seamless pipes are more suited for general mechanical and low-to-medium pressure applications. "Sch40" (Schedule 40) refers to a standardized wall thickness grade, ensuring consistent pressure-bearing capacity and structural stability. Combined, ASTM A106/A53 Sch40 seamless steel pipes integrate the advantages of both standards and the Sch40 thickness, making them widely used in oil and gas, petrochemical, municipal engineering, and industrial piping systems. Below are their core product features:

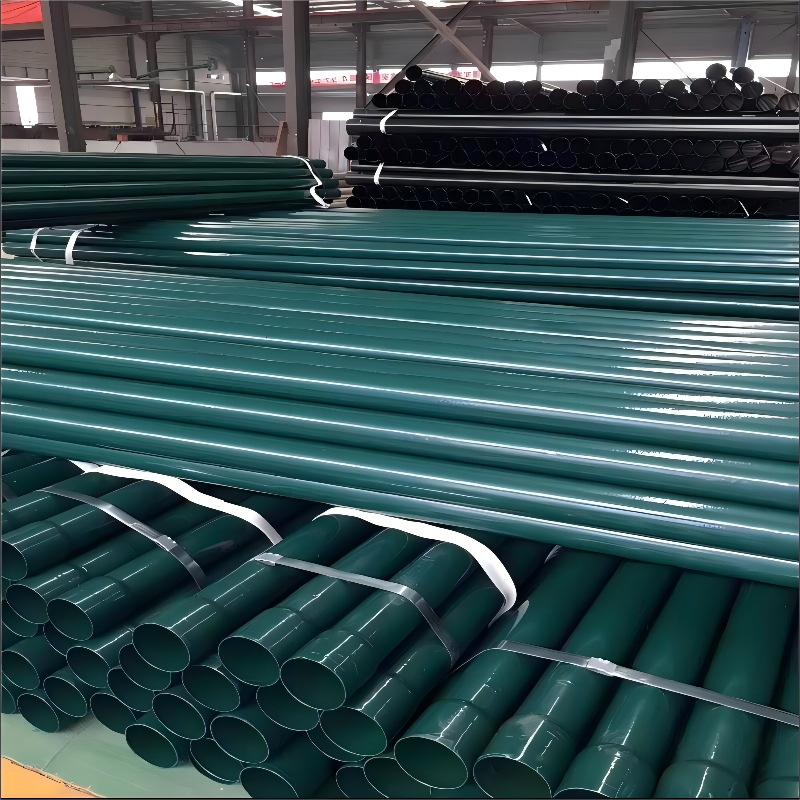

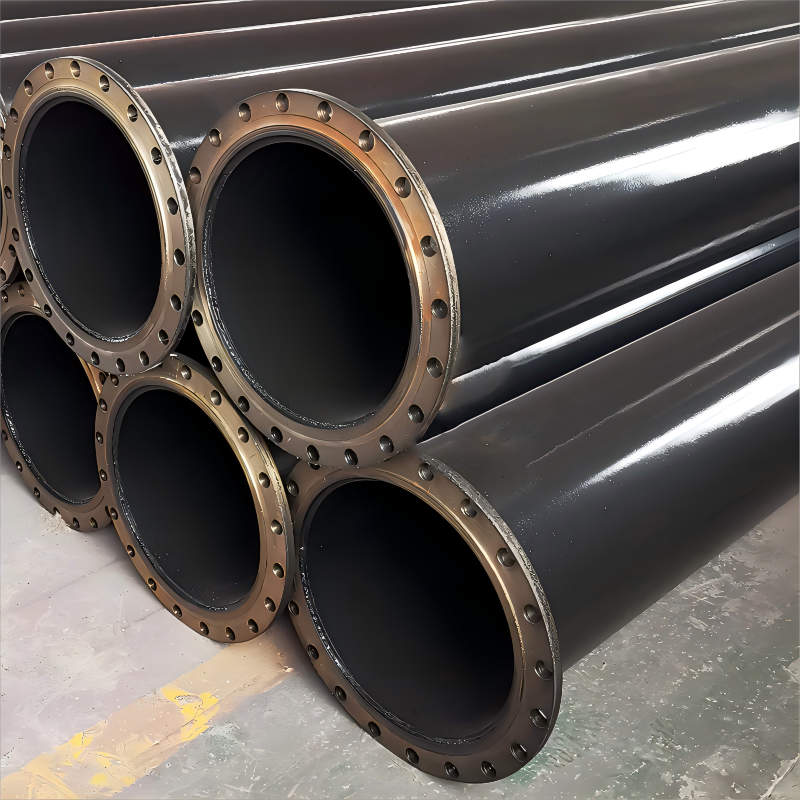

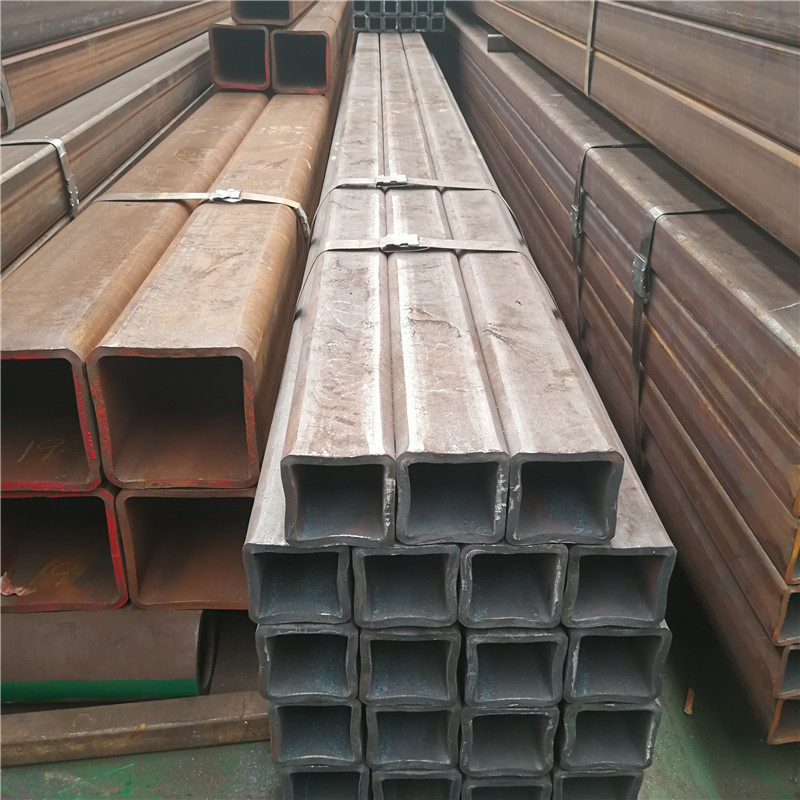

| Product name | Coated steel pipe |

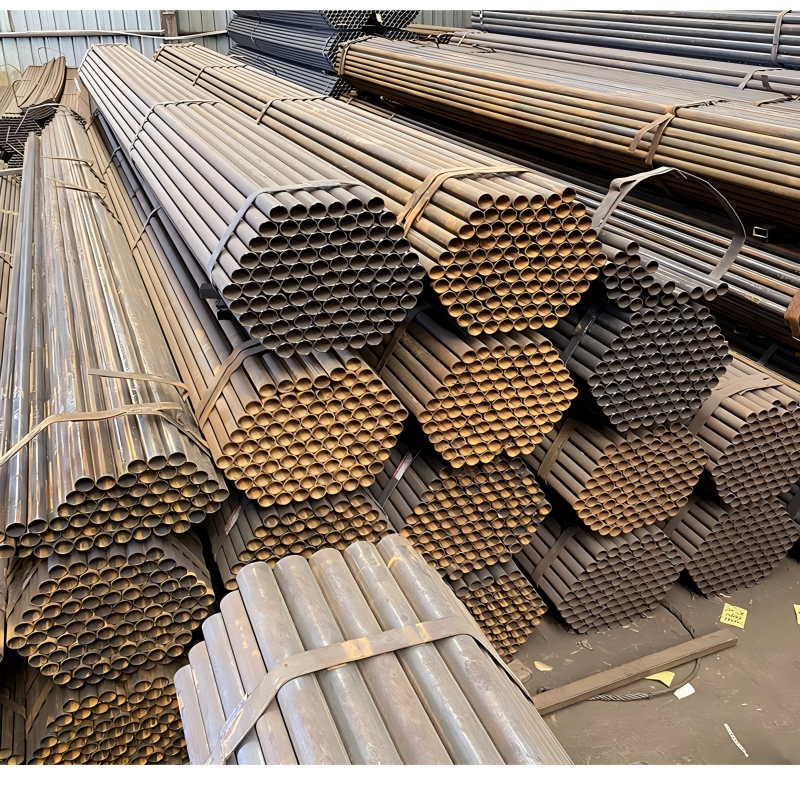

| Product material | Carbon steel |

| Color | Customized according to customer needs |

| Application scenario | Mine ventilation pipe Drain pipe Cable conduit etc |

| Surface treatment | Plastic coating |

| Length | Customized according to customer needs |

| Thickness | 2.0mm-130mm |

| Diameter | 1/4"-30" |

Details Images

Recommend Products

Concrete pump pipe

Concrete pump pipe

Product Packaging