Carbon steel seamless API pipes are crafted from premium carbon steel or low - alloy high - strength carbon steel. For instance, API 5L X65 seamless steel pipes have a minimum yield strength of 450 MPa and a tensile strength that can reach 570 MPa. They exhibit remarkable toughness and impact resistance, which allows them to endure substantial pressure and diverse external forces. This high - strength characteristic makes them suitable for applications like oil and gas pipelines, where they must withstand high - pressure fluid transportation over long distances.

These pipes can be treated with specialized anti - corrosion measures. Galvanizing, for example, involves coating the pipe with a layer of zinc, which acts as a sacrificial anode. When exposed to a corrosive environment, the zinc corrodes first, protecting the underlying carbon steel. Painting with corrosion - resistant coatings can also provide an additional barrier against corrosion. Another option is 3PE (three - layer polyethylene) coating, which offers enhanced protection in harsh conditions, such as in buried pipelines where they are exposed to soil moisture and chemical substances in the ground.

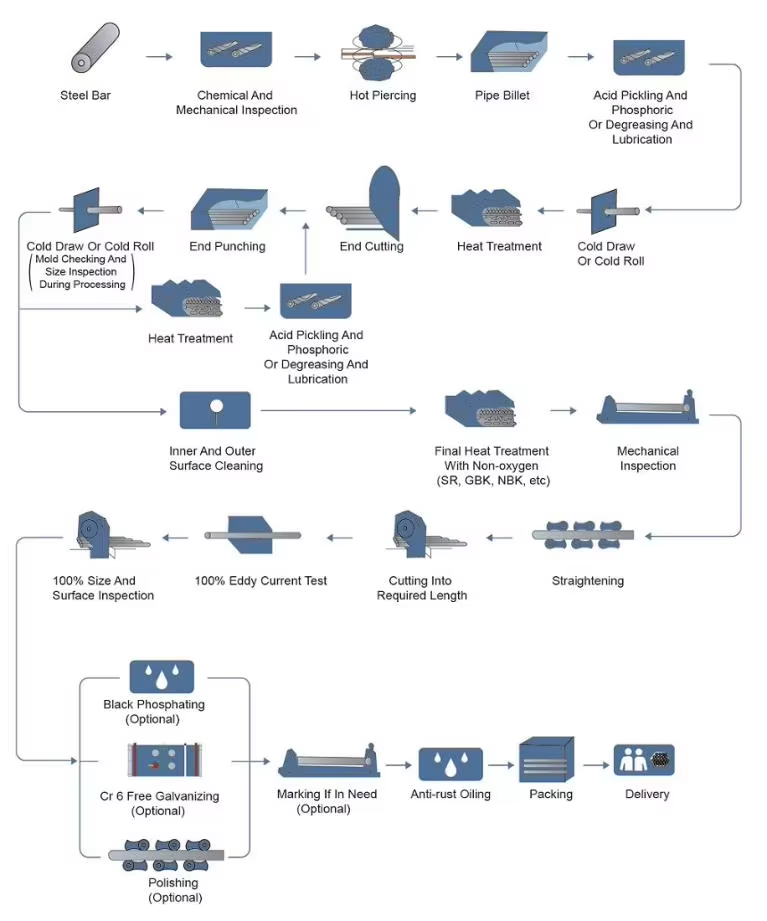

The manufacturing process of carbon steel seamless API pipes is highly precise. Regarding the outer diameter, wall thickness, and length, they all adhere to tight dimensional tolerances. Cold - drawn processes, for example, can achieve an outer diameter dimensional accuracy of ±0.05mm. The wall thickness is also carefully controlled, ensuring uniform thickness along the entire length of the pipe. The surface roughness is maintained within Ra0.8μm, which is crucial for applications where a smooth inner surface is required to minimize fluid friction, such as in fluid transportation pipelines.

Carbon steel seamless API pipes possess good weldability. They can be welded using a variety of welding procedures, including arc welding methods like shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux - cored arc welding (FCAW). During on - site installation, this property allows for easy connection of pipes, ensuring reliable joints. Skilled welders can achieve strong and leak - free welds, which is essential for constructing pipeline systems that need to maintain integrity under pressure.

There is a wide range of outer diameters, wall thicknesses, and material grades available to meet different engineering requirements. For example, the outer diameter of API 5L GR.B seamless steel pipes can span from 21.3mm to 762mm, while the wall thickness can range from 2.0mm to 140mm. According to API 5L standards, different steel grades such as X42, X52, X65, X70, etc., are available. Each grade has its specific mechanical properties, with higher - numbered grades generally having higher strength and better performance under more demanding conditions.