Casing tube, namely casing pipe, is mainly used in the oil and gas drilling industry to ensure the stability and safety of the wellbore. The following are its main product features:

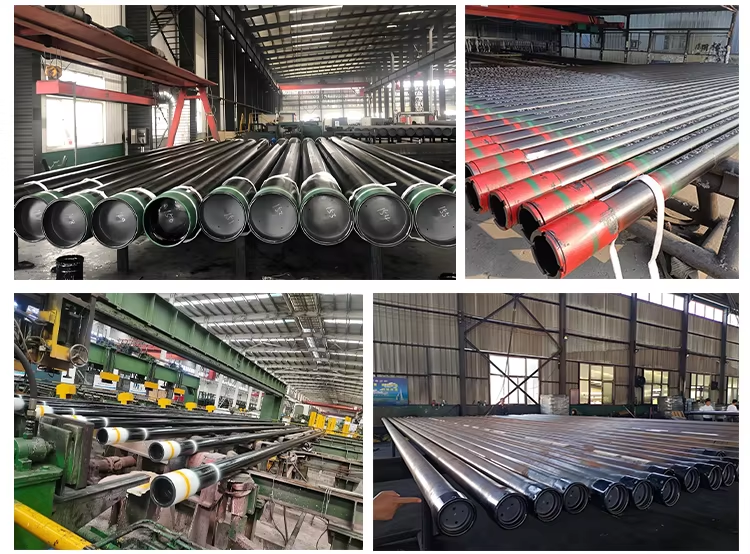

Good Corrosion Resistance: They are usually made of materials with certain corrosion - resistant properties, which can resist the erosion of formation fluids and other chemical substances, thereby prolonging the service life of the casing in the wellbore.

Diverse Specifications and Grades: Casing tubes come in a variety of outer diameters, wall thicknesses, and material grades to meet different well - drilling requirements. For example, according to API 5CT standards, there are different steel grades such as J55, K55, N80, L80, etc., with different yield strengths and other mechanical properties.

High - precision Thread Connections: The thread connections of casing tubes have high machining accuracy, which can ensure reliable connection and prevent fluid leakage. At the same time, it is convenient for field installation and disassembly operations.

Complying with Strict Quality Standards: The production of casing tubes needs to comply with strict industry standards and specifications, such as API standards. Manufacturers will conduct various quality inspections on casing tubes, including non - destructive testing, hydrostatic testing, and mechanical property testing, to ensure product quality and safety.

Playing Multiple Roles in the Wellbore: Different types of casing tubes, such as conductor casing, surface casing, intermediate casing, and production casing, play different roles in the wellbore. For example, conductor casing is used to protect loose near - surface formations and enable the circulation of drilling fluid; production casing is used to isolate production zones and contain formation pressures.