-80px

-80px

-80px

-80px

Production Process

Product Description

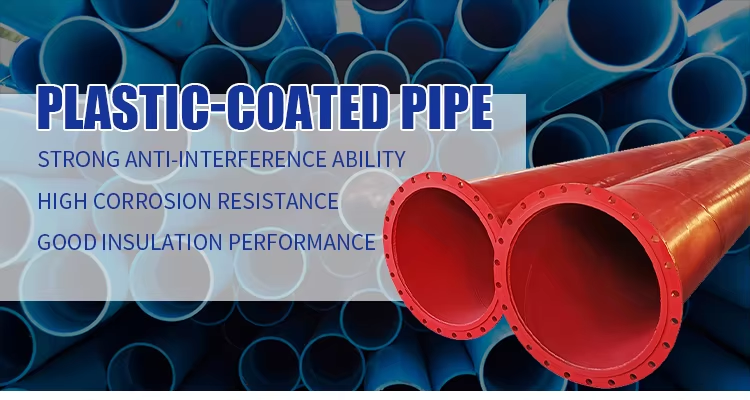

Corrosion Resistant Epoxy Coating Carbon Steel Pipe combines the high mechanical strength of carbon steel with the excellent chemical inertness of epoxy coatings. It addresses the core limitation of bare carbon steel (susceptibility to rust and corrosion in moist, chemical, or harsh environments) while retaining the steel’s structural advantages. The epoxy coating—applied via electrostatic spraying, dipping, or brushing—forms a dense, adhesion-strong barrier that isolates the steel base from corrosive media (e.g., water, salt, acids, alkalis). Below are its key product features:

Packing & Delivery

Application

Main application fields

Water supply and drainage pipes

Fire sprinkler system

Natural gas, gas, oil pipeline

Chemical, pharmaceutical, food pipeline

Slurry, powder, sand and gravel pipeline

Cable protection conduit

Certifications