-80px

-80px

-80px

-80px

Production Process

Product Description

Galvanized Steel Pipe (also known as GI Tube, short for “Galvanized Iron Tube”) processed via the hot dip galvanization (HDG) method is a widely used piping and structural product. It involves immersing carbon steel pipes in a molten zinc bath (typically at 440–460°C), forming a dense, metallurgically bonded zinc-iron alloy layer and an outer pure zinc layer on the surface. This process endows the pipe with exceptional corrosion resistance, mechanical durability, and cost-effectiveness, making it suitable for plumbing, construction, infrastructure, and industrial applications. Below are its key features:

Packing & Delivery

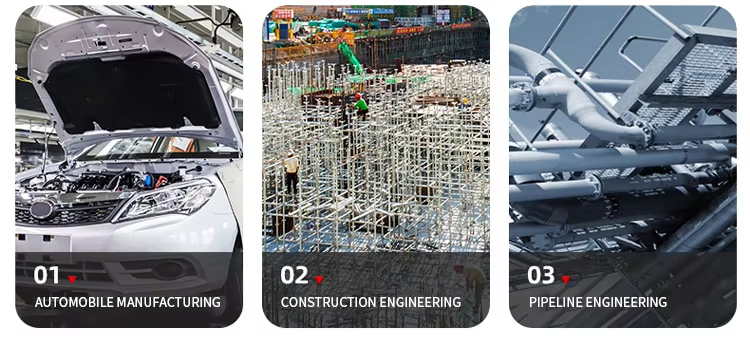

Application

Galvanized steel pipes for structure: used for building and structural support, with strong load-bearing capacity.

Galvanized steel pipes for fluid transportation: They are used for transporting fluids such as water, natural gas, and oil, and have excellent sealing and anti-corrosion properties.

Certifications