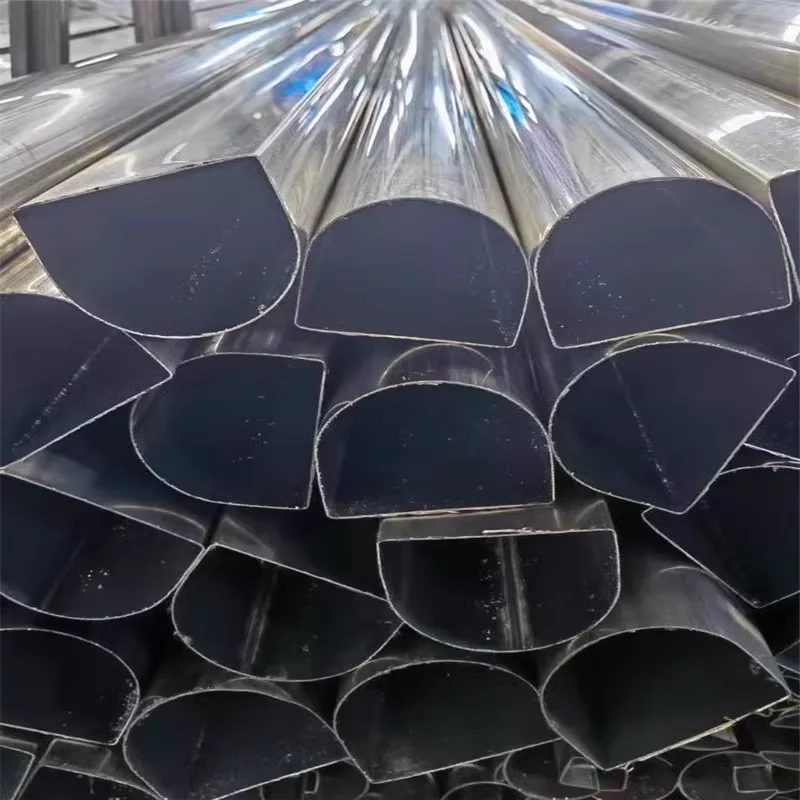

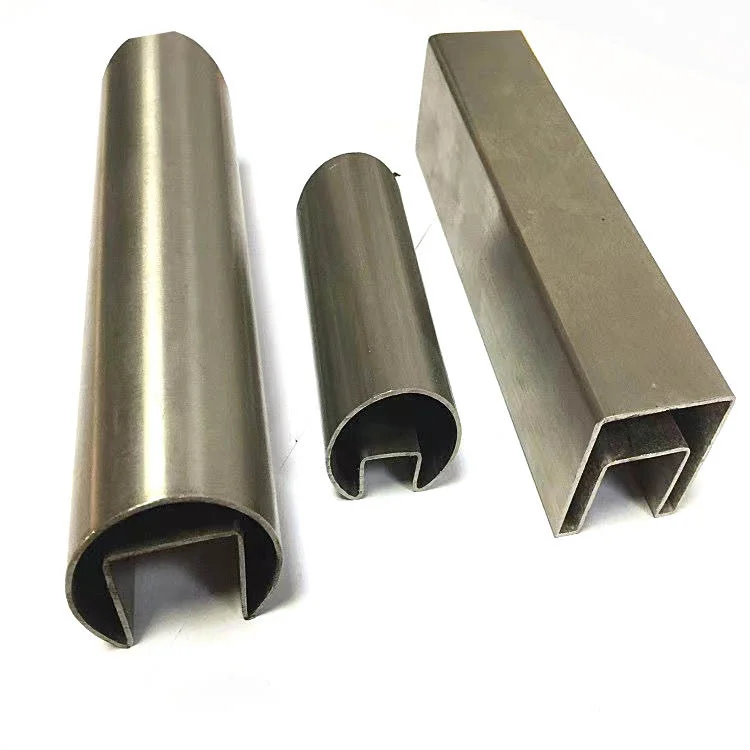

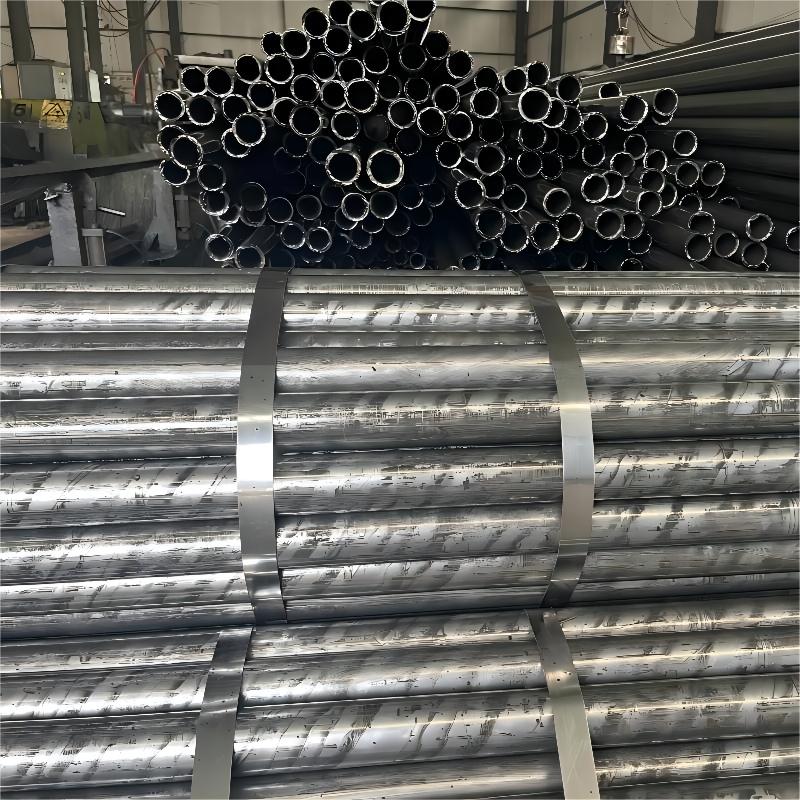

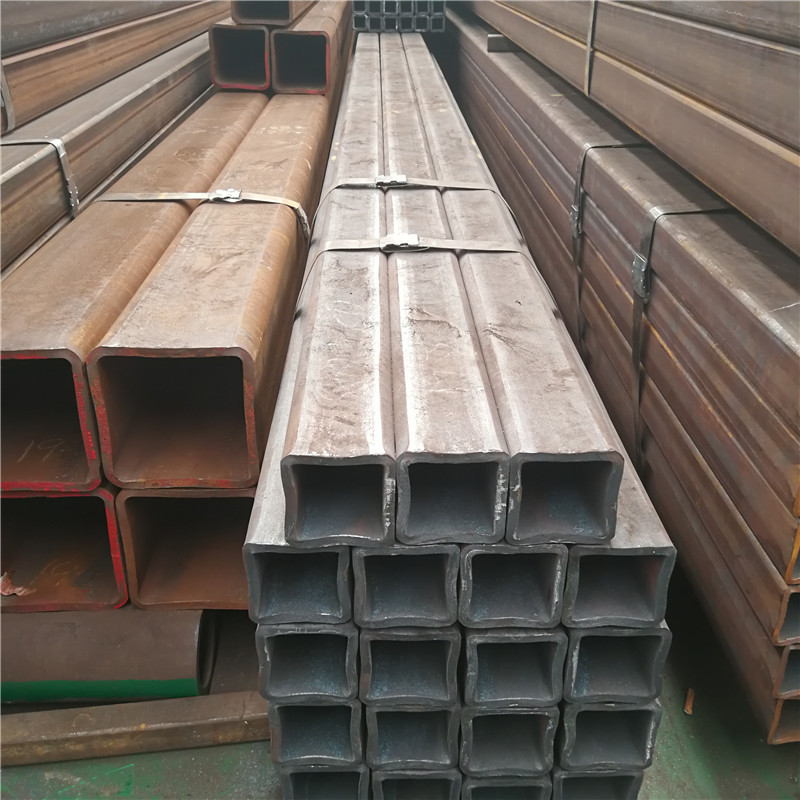

Product name | Special shape pipes |

Standard | AISI, ASTM, DIN, JIS, GB,JIS, SUS, EN, etc. |

Material | 10#,20#,45#,ST37, ST52, A106, A53, Q235, Q345, Q195, Q215, 6061, etc. |

Technology | Hot rolled, Cold rolled, Cold -drawing |

Application | Widely used in Structure, Accessorize, liquid delivery (pump well, gas, water), construction pipe, structuralpipe (greenhouse

structure, fence post), curtain wall, machinery part ect. |

Packing | Standard Sea-worthy Packing, according to customer's requirement |