-80px

-80px

-80px

-80px

Product Information

Superior Corrosion Resistance

The hot-dip galvanizing process involves immersing the flat steel bar in a bath of molten zinc (typically at 450°C/842°F), forming a metallurgical bond between the zinc and the base steel. This creates a thick, uniform zinc coating (usually 85-120 microns) that acts as a physical barrier against moisture, oxygen, and corrosive elements (e.g., salt, chemicals, and industrial pollutants).

Unlike other coating methods (e.g., painting), the zinc coating provides cathodic protection: if the coating is scratched or damaged, the surrounding zinc corrodes preferentially, protecting the exposed steel from rust.

High Strength and Structural Integrity

The base material (flat steel) retains its inherent mechanical properties, including high tensile strength (typically 300-500 MPa) and rigidity, making it suitable for load-bearing applications (e.g., structural supports, brackets, and framework).

The galvanizing process does not compromise the steel’s strength, ensuring the bar maintains its structural performance even in harsh environments.

Uniform and Durable Coating

The hot-dip method ensures complete coverage of the flat steel bar, including edges, corners, and recesses—areas often missed by spray or brush coatings. This uniformity eliminates weak points where corrosion could start.

The zinc coating is highly adherent and resistant to chipping, peeling, or cracking, even under mechanical stress (e.g., bending, cutting, or installation).

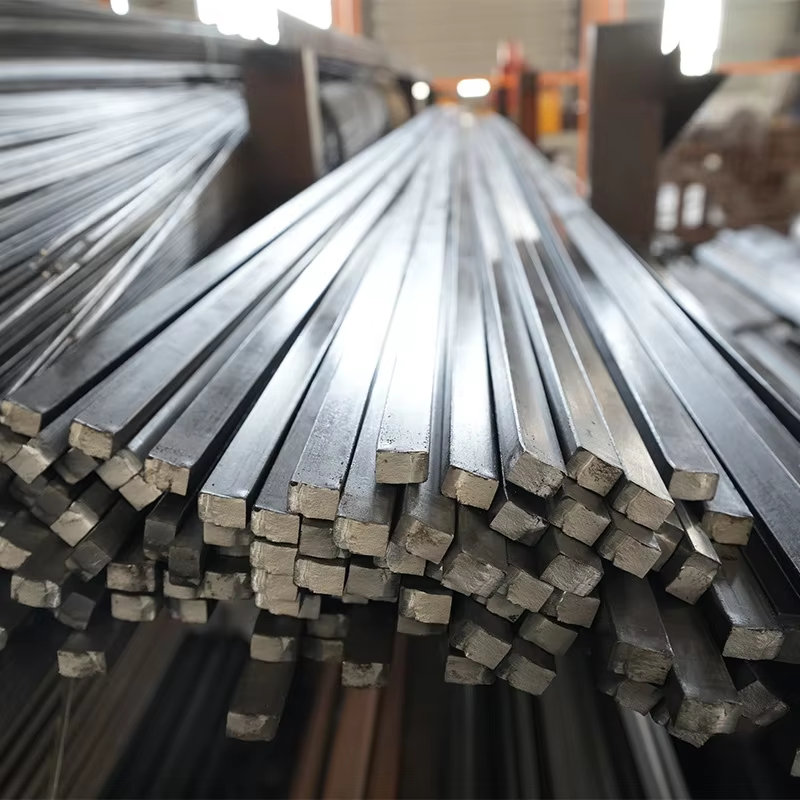

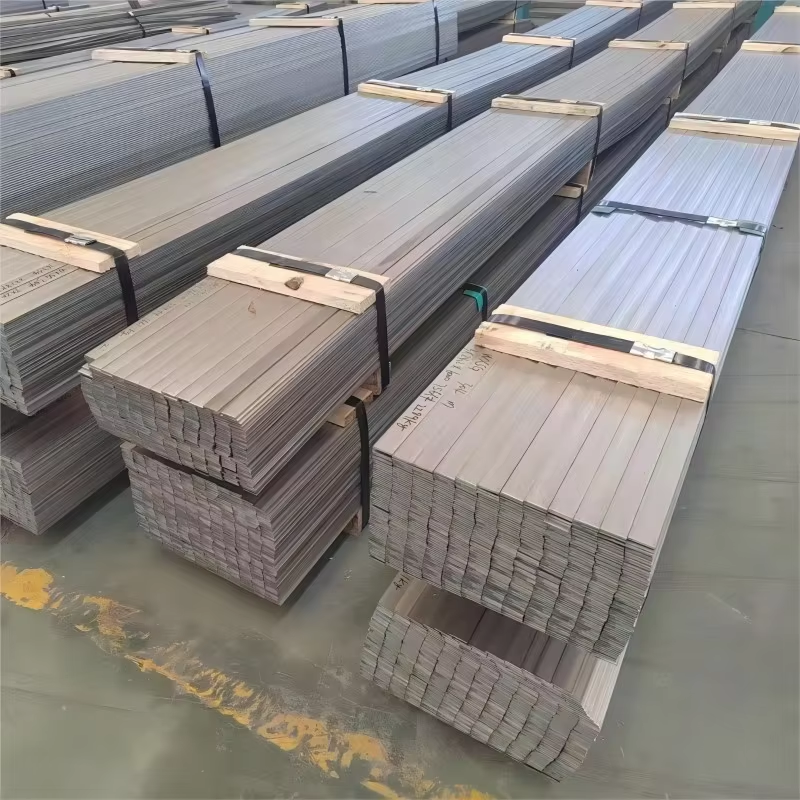

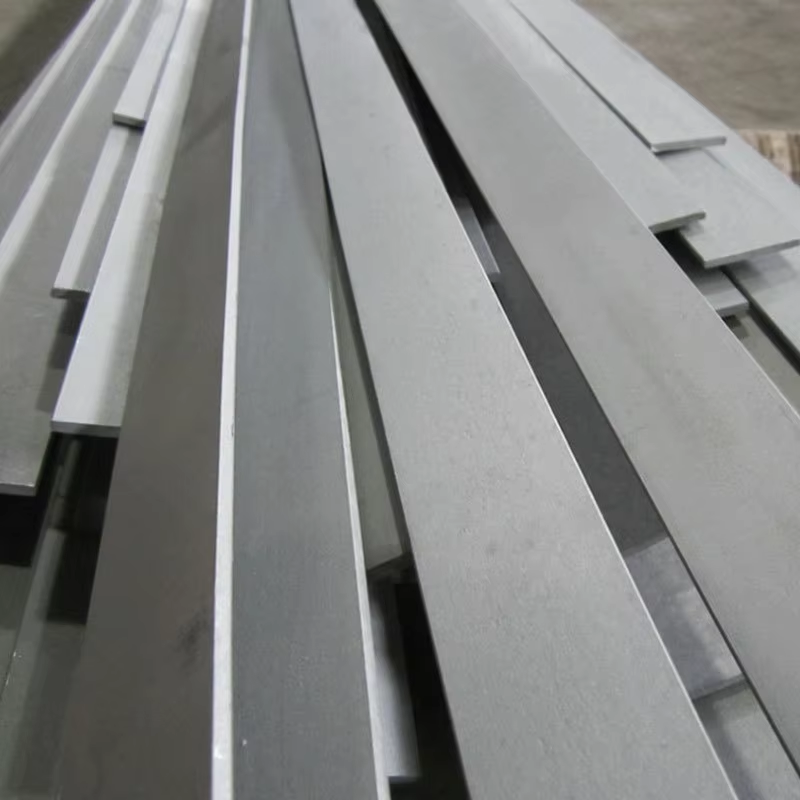

Product Display

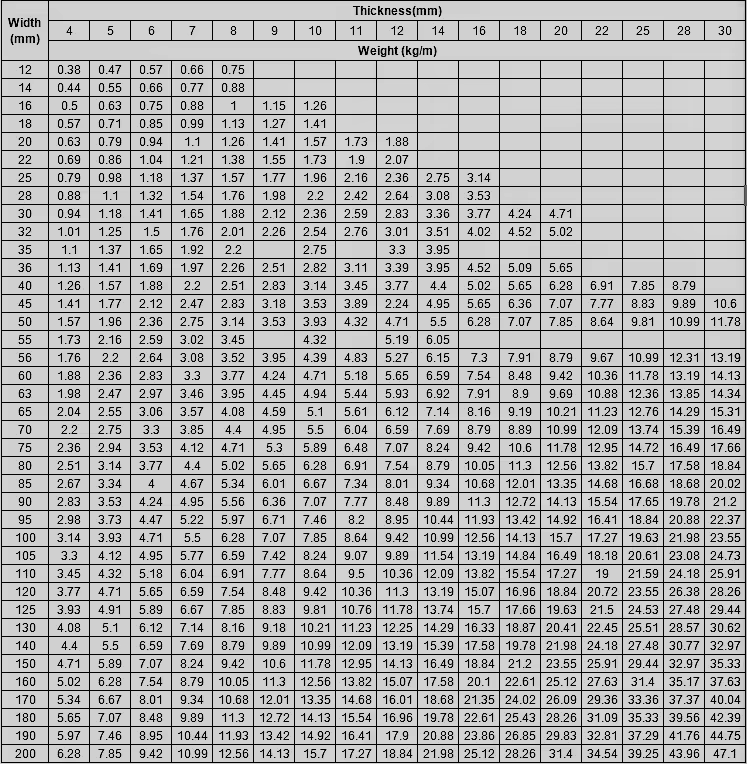

Specification

| Item | value |

| Place of Origin | Shandong,China |

| Standard | DIN |

| Grade | W1 steel |

| Oiled or Non-oiled | Non-oiled |

| Delivery Time | 15-21 days |

| Thickness | 2-100mm |

| Surface Treatment | Non-oiled |

| Hardness | Full Hard |

| Skin Pass | Yes |

| Brand Name | ZCXH |

| Application | Construation,Machining Parts |

| Width | 600mm - 1219mm |

| Certificate | API, ce, SNI, BIS, SASO, PVOC, GS, ISO9001 |

| Tolerance | ±1% |

| Processing Service | Welding, Punching, Cutting, Bending, Decoiling, Annealed, Black Annealed |

| Product Name | Cold Rolled Steel Coil |

| Technique | Cold Rolled Hot Rolled |

| Material | SS304/SS316/Q235/Q235B/Q345/Q345B/SS400 |

| Keyword | Flat Bar |

| Surface | Bright |

| MOQ | 1 Ton |

Production Workshop

Certifications

Products Application

Packaging and Transportation

FAQ

Q:How long is your delivery time?

A:Samples: 7 - 10 working days; bulk production: 10 - 15 working days. It also should be depend on what kind of product and the quantity you require

Q:Do you provide samples, is it free or extra?

A:Yes, We'd like to provide samples before the bulk production, for the custom metal stamping samples it can be free after making mold;

Yes, we can do OEM according to your requirement.

Do you provide ODM/OEM service? Yes, OEM / ODM is welcome, Please feel free to send us your drawing or samplesIf

Q:You make poor quality goods, will you refund our fund?

A:As a matter of fact, we wont take a chance to do poor quality products. Meanwhile, we manufacture goods quality products until your satisfaction.

Q:Are you making by yourself?

A:Yes, we are. we have our own factory and showroom. Warmly welcome to visiting our factory at any time.

Q:What is your terms of payment?

A:T/T, 30% as deposit, and 70% balance before delivery

Q:How can i get the quotation?

A:Please send us information for quote; drawing, material, weight, quantity and request, we can accept PDF.ISGS,DwgSTEP file format. If you don't have draw-ing, please send the sample to us, we can quote base on your sample too