-80px

-80px

-80px

-80px

Product Description

Hot dipped galvanized pipes are produced by immersing steel pipes in a bath of molten zinc at around 450°C. This process creates a metallurgically bonded zinc-iron alloy layer and an outer pure zinc layer on the pipe surface, endowing them with a unique set of properties that make them highly sought-after in numerous industries.

Hot dipped galvanized pipes are manufactured by immersing steel pipes in molten zinc. A galvanized layer is formed through chemical reaction and physical adhesion between zinc and the steel surface, belonging to a "post-galvanization" process (galvanization is done after the steel pipe is formed). Their core features focus on "strong anti-corrosion and high adaptability":

Superior Anti-Corrosion Performance & Long Service Life

The galvanized layer consists of a "zinc-iron alloy layer" and a "pure zinc layer," with a thickness of over 85μm (far higher than other galvanization processes). It tightly covers the steel pipe surface, effectively isolating corrosive media such as air, moisture, acid, and alkali. In ordinary atmospheric environments, the service life can reach 20-50 years, which is 5-10 times that of bare steel pipes. Even in humid, coastal salt-spray, or mild industrial pollution environments, it can significantly delay rusting and reduce long-term maintenance costs.

Strong Adhesion of Galvanized Layer, Impact & Wear Resistance

During the hot dipped galvanization process, zinc and steel form a metallurgical bond. The resulting zinc-iron alloy layer has high hardness (HV≥250) and firm bonding with the base material, which is not easy to fall off due to collisions during handling and installation or friction during long-term use. Compared with cold galvanization (electrogalvanization), its galvanized layer has better anti-peeling performance and can adapt to outdoor, underground, and other scenarios vulnerable to external forces.

Product Display

Company Profile

Applications

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

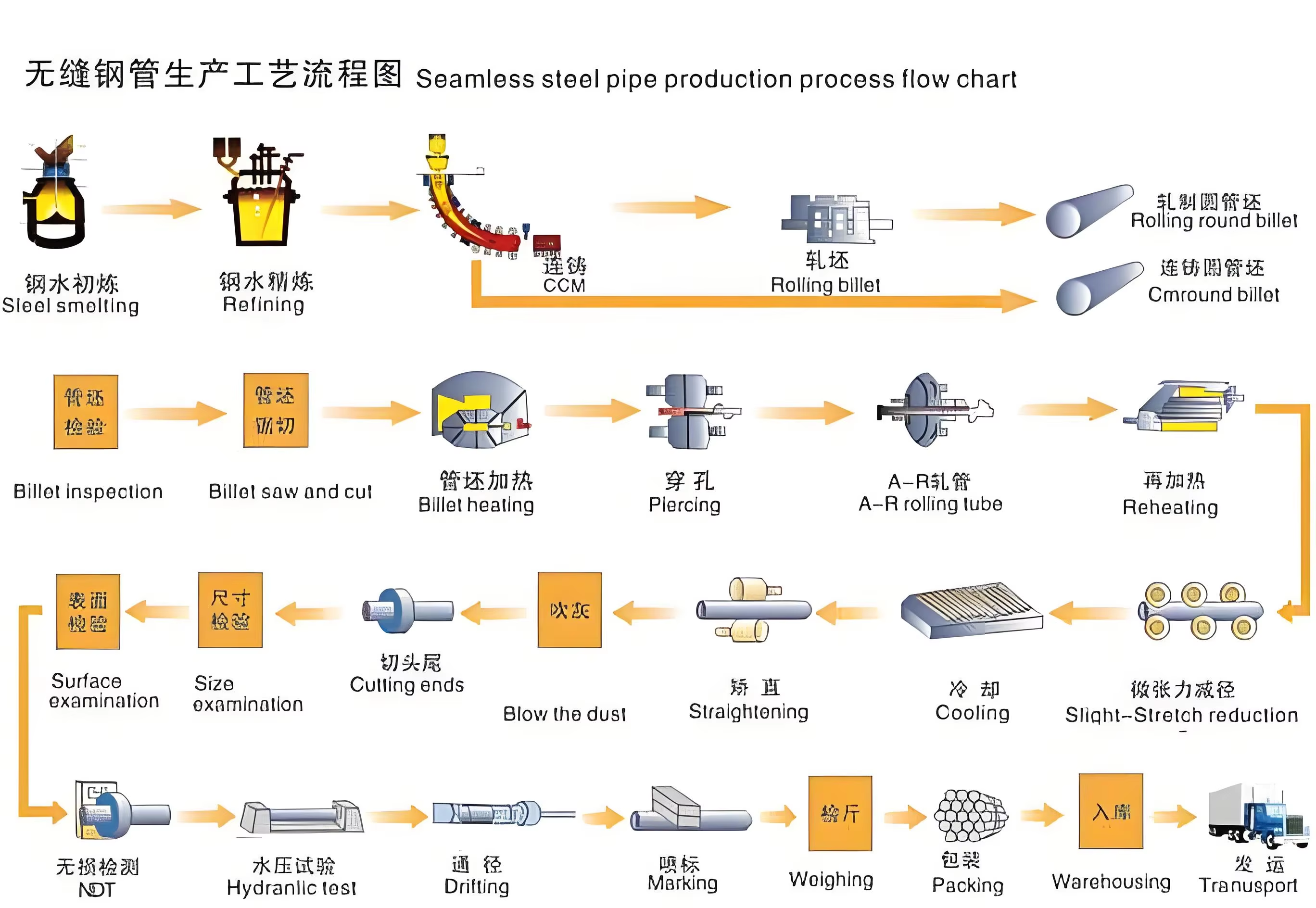

Manufacturing Technique