-80px

-80px

-80px

-80px

Production Process

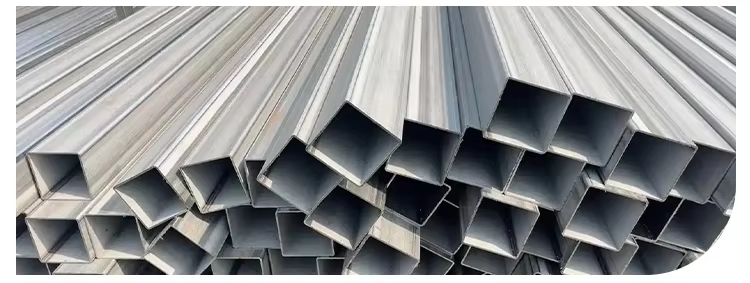

Product Description

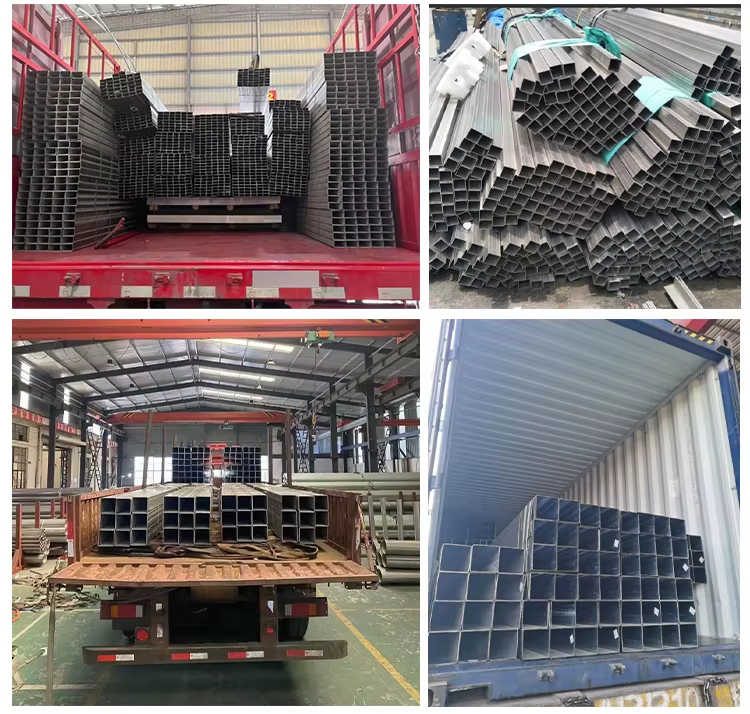

Packing & Delivery

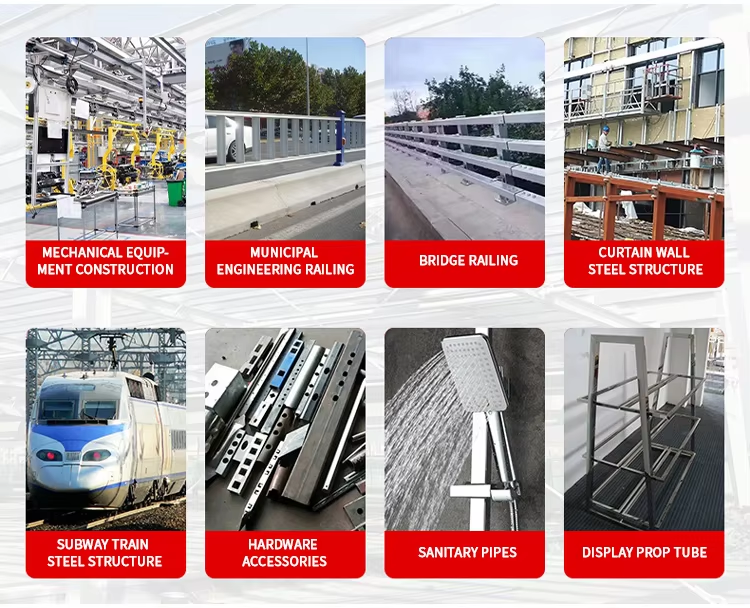

Application

Industrial equipment supports: Used for equipment support, pipeline supports, and frames of automated devices in factories and workshops. They are durable, reliable, and easy to maintain.

Certifications