-80px

-80px

-80px

-80px

Production Process

Product Description

Packing & Delivery

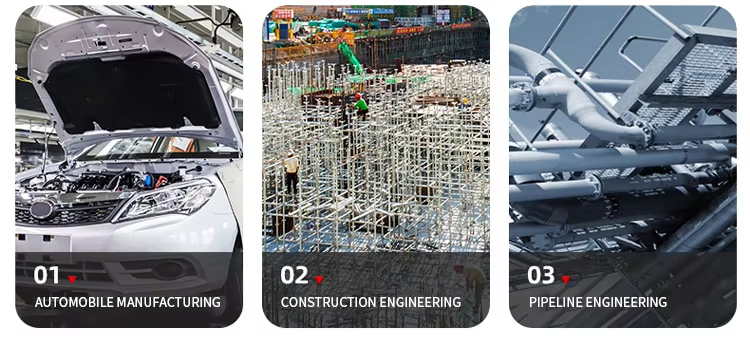

Application

Galvanized steel pipes for structure: used for building and structural support, with strong load-bearing capacity.

Galvanized steel pipes for fluid transportation: They are used for transporting fluids such as water, natural gas, and oil, and have excellent sealing and anti-corrosion properties.

Certifications