-80px

-80px

-80px

-80px

Product Description

Large Diameter Prestressed Metal Corrugated Pipes with an oval section, manufactured in compliance with ASTM standards (e.g., ASTM A797 for corrugated steel pipes, ASTM A106 for base metal), are specialized structural and fluid-transmission components. Their design integrates "large-diameter capacity," "prestressed reinforcement," "oval section adaptability," and "corrugated structural strength," making them ideal for underground drainage, highway culverts, and large-scale infrastructure projects. Core features are detailed below:

Metal bellows

Metal bellows are continuous/non-cracked/non-leaking 1.Smooth cut 2.Stable performance

3.Easy to install and use

Various specifications can be customized

1.The surface is bright and has no burrs.

1.Good bending performance. The corrugated tube body is bendable, which is easy to install. Use PVC + metal hose to effectively protect the cable.

2.Wear-resistant The plastic-coated hose is made of thickened material, which greatly improves the tensile strength of the hose

The plastic-coated hose is made of thickened material, which greatly improves the tensile strength of the hose

3.High temperature resistant The surface of the plastic coated hose is made of PVC material and fire retardant is added to the PVC plastic

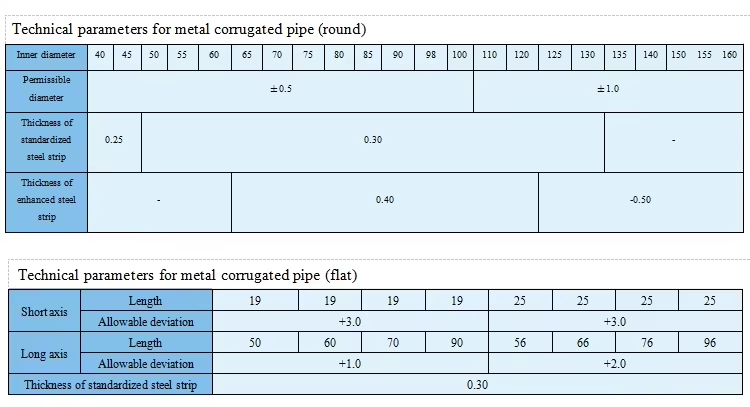

Specification

Our Products

Application