-80px

-80px

-80px

-80px

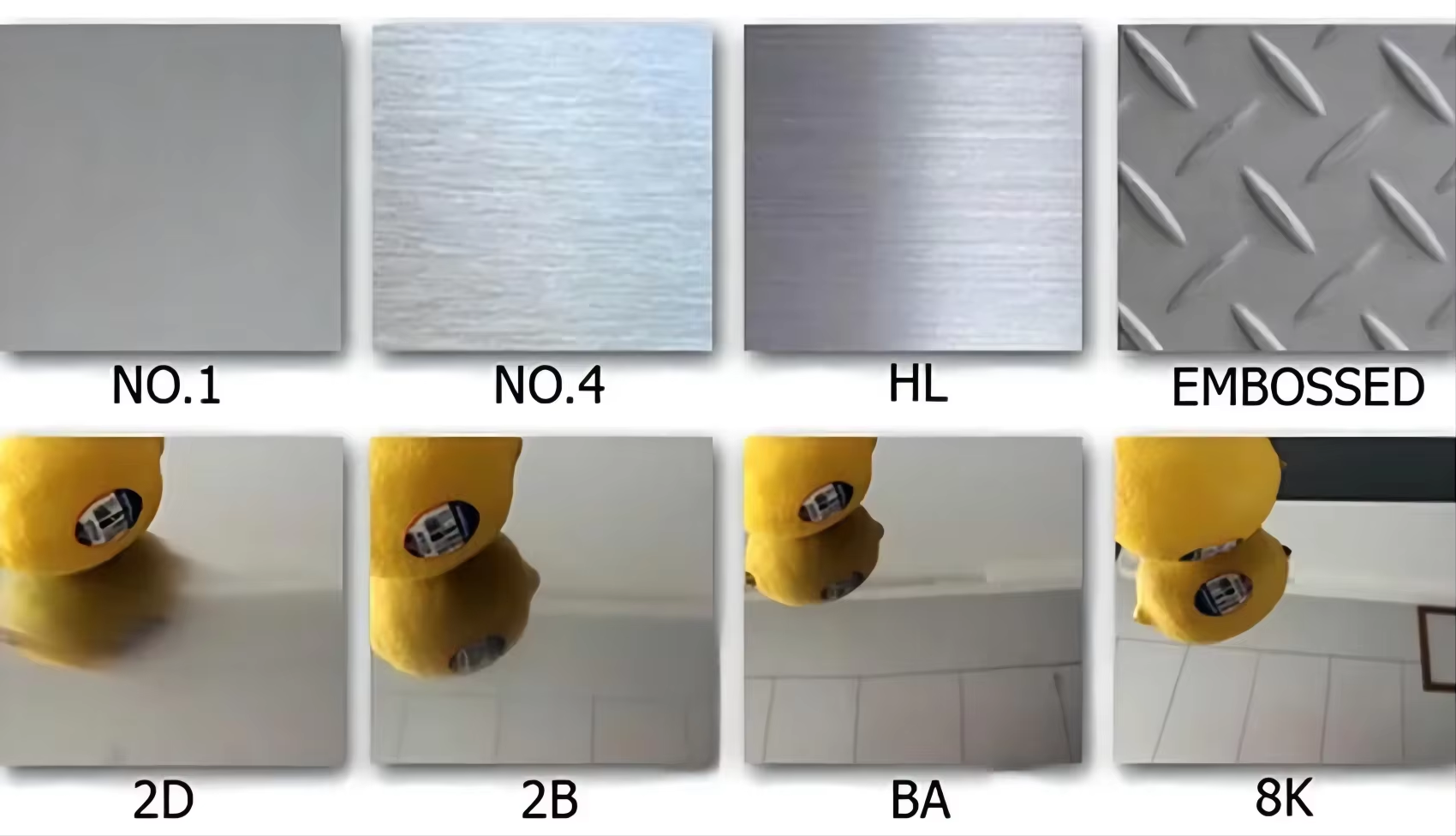

Product Surface

| Surface finish | Characteristics & Application |

| NO.1 | Hot-rolled surface,annealed and pickled,can be used as cold-rolling material,industial tanks and chem i cal devices. |

| 2D | Cold-rolled, an nealed and pick led with out skinpassing the dull prod ucts can be used as auto mo bile parts, build ing materrials and pipings. |

| 2B | The surface brightness and flatness of NO.2B is better than NO.2D. Then through a special surfacetreament to improve its mechamical properties, N02B could nearly satisfy com pre hen sive uses. |

| NO.3 | Polished with abra sive belt of grit #100#120,have bet ter bright ness with dis con tin u ous coarse stria, used as in ner and ex ter nal or na ments for building, elec tri cal ap pli anc es and kitchen uten sils etc. |

| NO.4 | Polished with abrasive belt of grit #150#180, have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtud buildinginner and external ornaments electrical appliances, kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-320 on the No.4 finish and has continuous streaks, mainly used as building ornaments, elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright an nealed and skin passed, the prod uct has ex cel lent bright ness and good re flex iv i ty like mirror, used for lectrical appliances, mirror, kitch en apparatus, or na ment ma te ri als etc. |

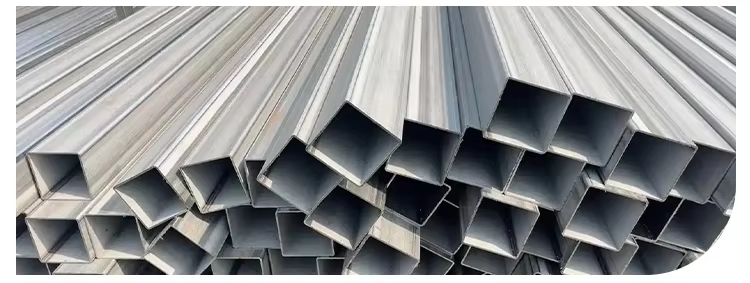

Production Process

Product Description

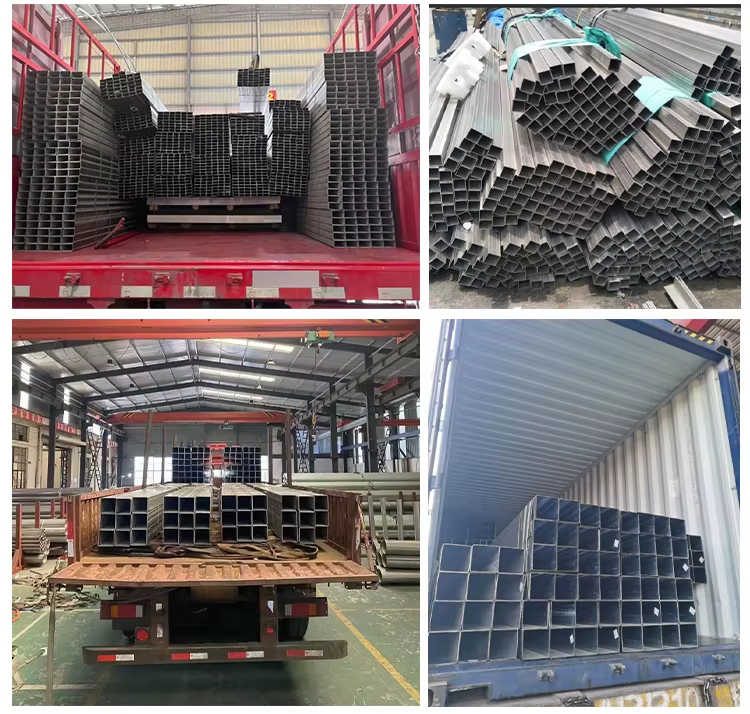

Packing & Delivery

Certifications