316Ti is a modified version of the classic 316 stainless steel, with the addition of titanium (Ti, typically 0.5%-1.0% in content) while retaining 316’s basic alloy composition (Cr: approximately 16%-18%, Ni: approximately 10%-14%, Mo: approximately 2%-3%). The introduction of titanium addresses a critical defect of 316 in high-temperature environments, resulting in unique advantages:

Significantly Enhanced Intergranular Corrosion Resistance

316 stainless steel tends to form chromium carbides (Cr₂₃C₆) when carbon combines with chromium in the "sensitization temperature range" (425-815°C). This leads to a reduction in chromium content at grain boundaries (creating a "chromium-depleted zone") and triggers intergranular corrosion. However, titanium in 316Ti preferentially combines with carbon to form titanium carbides (TiC), preventing the precipitation of chromium. Even when used in long-term high-temperature environments (e.g., boilers, heat exchangers), it avoids intergranular corrosion and significantly extends the pipe’s service life.

Markedly Improved High-Temperature Strength

The strengthening effect of titanium enables 316Ti to maintain stable mechanical strength at high temperatures (with a maximum tolerance of 800-900°C, far higher than 316’s 650°C). It is less prone to deformation or fracture, making it particularly suitable for applications involving high-temperature fluid transport (e.g., high-temperature steam, hot oil) or high-temperature industrial environments (e.g., petrochemical cracking units).

Retained Excellent General Corrosion Resistance

While optimizing high-temperature performance, 316Ti inherits 316’s core corrosion resistance advantages from molybdenum (Mo). It exhibits strong resistance to corrosion from acidic media (e.g., dilute sulfuric acid, phosphoric acid), alkaline solutions, and chloride-containing environments (e.g., seawater, coastal atmospheric environments). This makes it far more corrosion-resistant than 304 stainless steel in harsh corrosive scenarios.

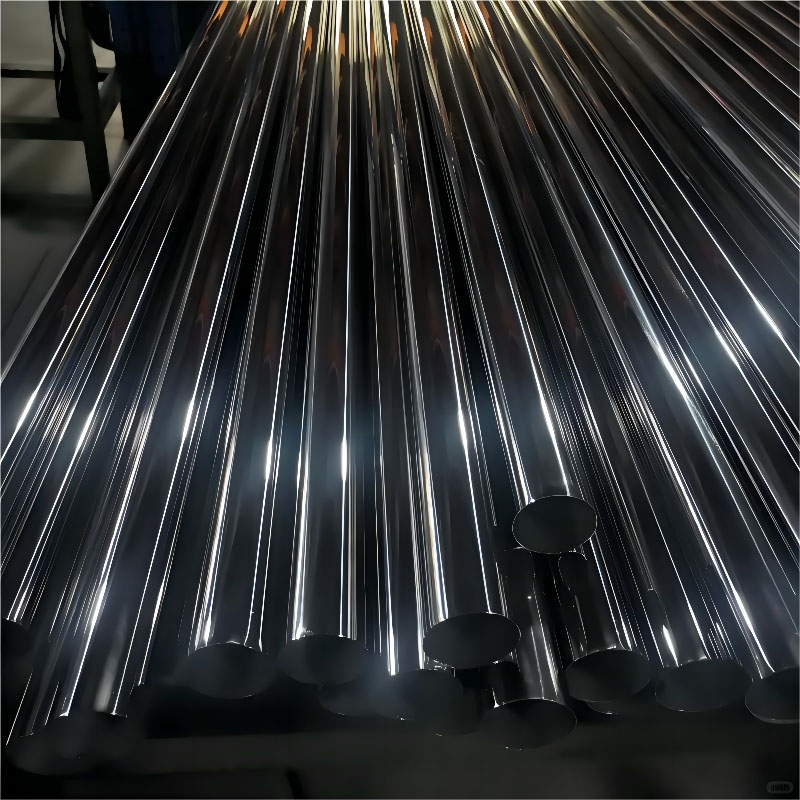

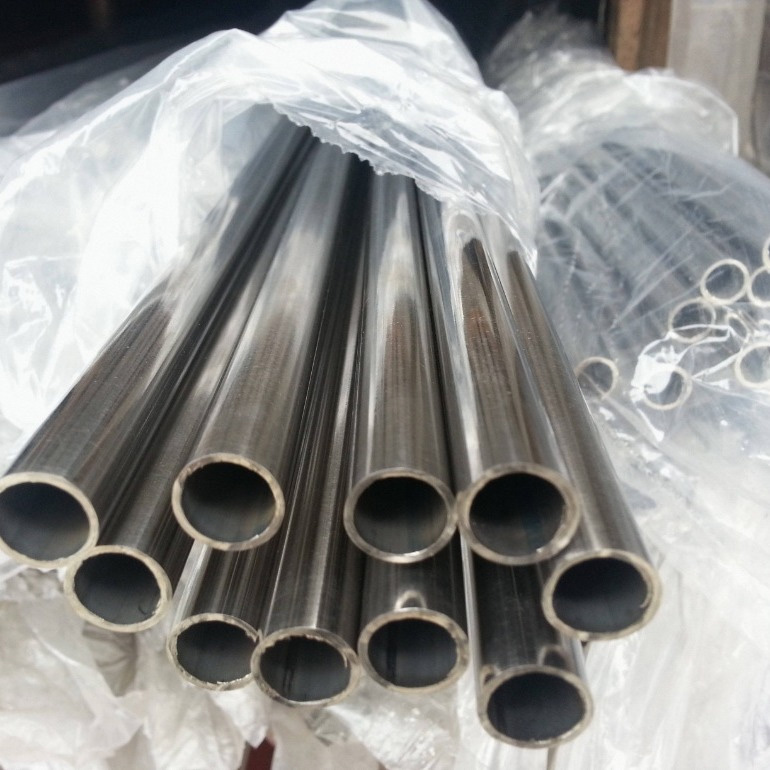

The "4-inch" specification is a widely used nominal size in industrial piping systems, with dimensional features that align with practical application needs:

Standardized Outer Diameter (OD) and Wall Thickness

According to common standards (e.g., ASTM A312 for seamless pipes, ASTM A480 for welded pipes), the actual outer diameter of a 4-inch stainless steel pipe is approximately 114.3mm (a fixed value for nominal sizes).

Wall thickness varies by pressure rating (e.g., SCH 10, SCH 40, SCH 80): For example, SCH 40 (standard wall thickness) has a wall thickness of about 6.02mm, while SCH 80 (thick wall) has a wall thickness of about 8.56mm. This allows flexible selection based on pressure requirements (e.g., SCH 80 for high-pressure fluid transport, SCH 10 for low-pressure scenarios).

Wide Compatibility with Piping Systems

4-inch pipes match common industrial pipe fittings (e.g., 4-inch flanges, elbows, tees) and connection methods (e.g., welding, threaded connections, flange connections). They can be seamlessly integrated into existing medium-to-large flow piping systems (e.g., industrial water supply, chemical fluid transport), avoiding issues such as mismatched connections or flow restrictions.

Balanced Flow Capacity and Structural Stability

The inner diameter of a 4-inch pipe (e.g., ~102.3mm for SCH 40) provides sufficient cross-sectional area for fluid transport, ensuring high flow rates (suitable for medium-to-large flow demands, such as industrial process water, cooling water circulation). Meanwhile, the standardized wall thickness ensures structural rigidity, preventing pipe sagging or damage during installation and operation.