-80px

-80px

-80px

-80px

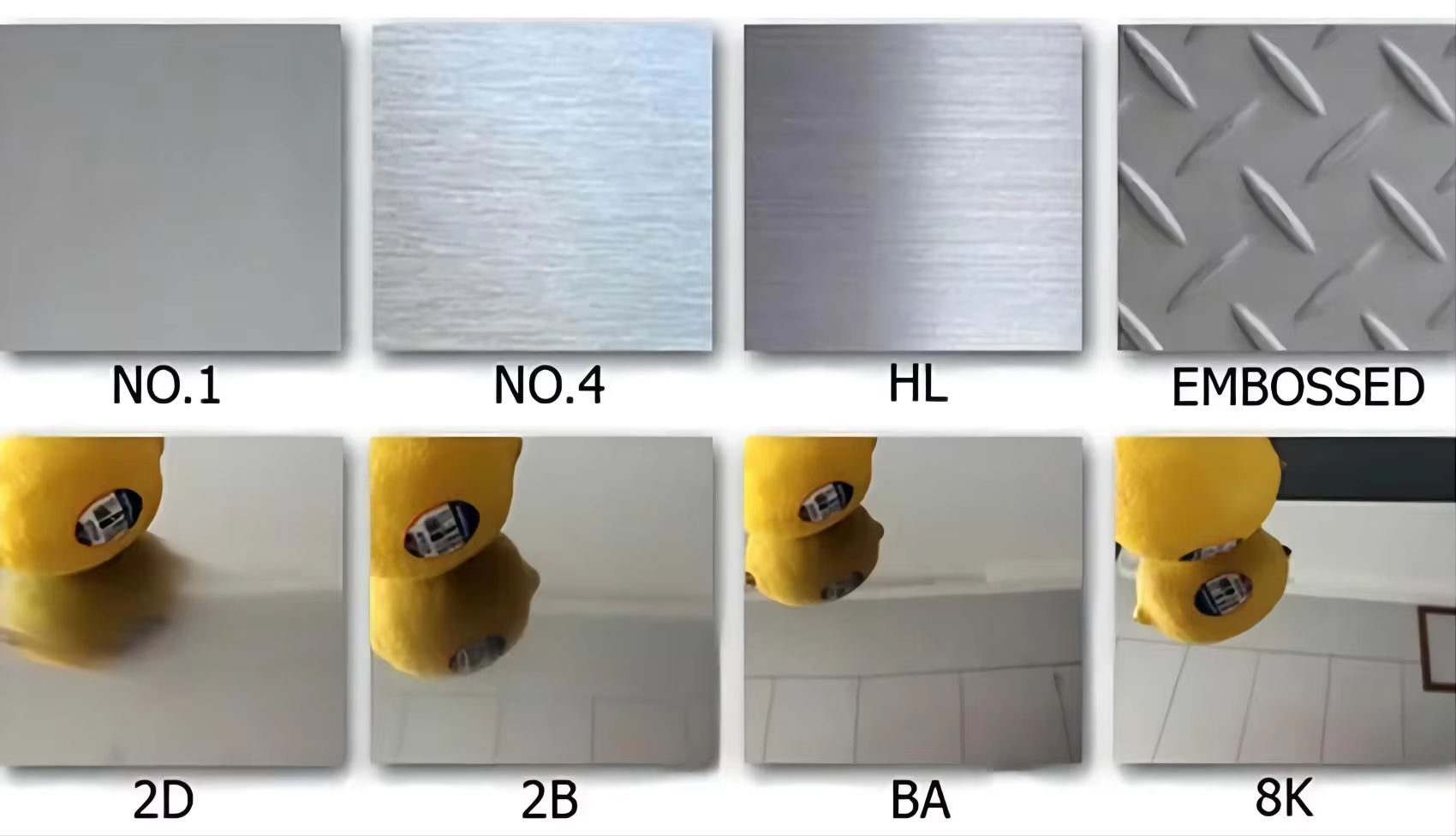

Product Surface

| Surface finish | Characteristics & Application |

| NO.1 | Hot-rolled surface,annealed and pickled,can be used as cold-rolling material,industial tanks and chem i cal devices. |

| 2D | Cold-rolled, an nealed and pick led with out skinpassing the dull prod ucts can be used as auto mo bile parts, build ing materrials and pipings. |

| 2B | The surface brightness and flatness of NO.2B is better than NO.2D. Then through a special surfacetreament to improve its mechamical properties, N02B could nearly satisfy com pre hen sive uses. |

| NO.3 | Polished with abra sive belt of grit #100#120,have bet ter bright ness with dis con tin u ous coarse stria, used as in ner and ex ter nal or na ments for building, elec tri cal ap pli anc es and kitchen uten sils etc. |

| NO.4 | Polished with abrasive belt of grit #150#180, have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtud buildinginner and external ornaments electrical appliances, kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-320 on the No.4 finish and has continuous streaks, mainly used as building ornaments, elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright an nealed and skin passed, the prod uct has ex cel lent bright ness and good re flex iv i ty like mirror, used for lectrical appliances, mirror, kitch en apparatus, or na ment ma te ri als etc. |

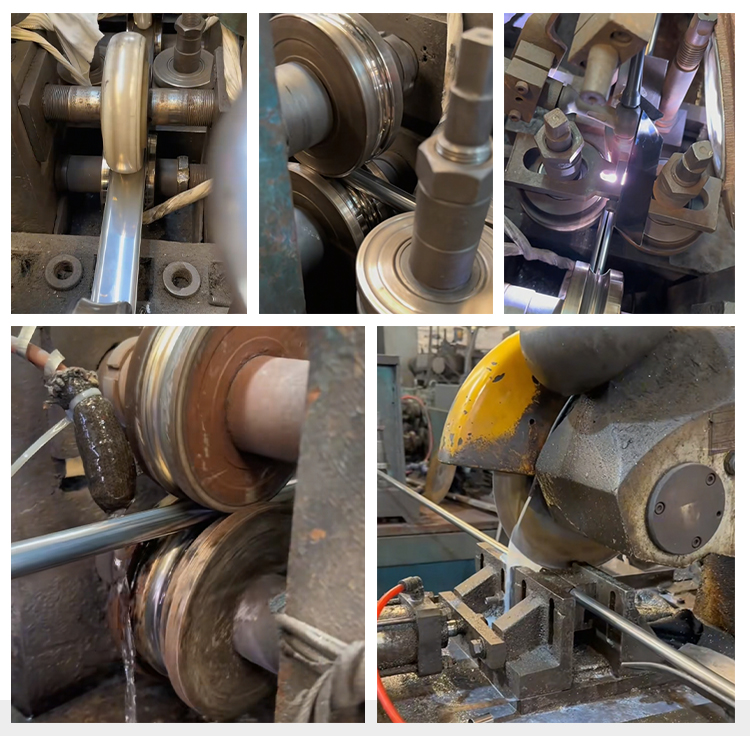

Production Process

Excellent corrosion resistance

The chromium element in the stainless steel pipe can form an oxide protective film on the surface of the pipe to prevent rust, especially suitable for wet, acid-alkali environment, suitable for chemical industry, Marine engineering and other occasions with high requirements for corrosion resistance.

High temperature resistance

Stainless steel pipes can maintain good physical properties and structural stability in high temperature environments, and are suitable for boilers, heat exchangers and other equipment requiring high temperature resistant materials.

Good strength and ductility

Stainless steel pipes have high strength and good ductility, suitable for a variety of processing methods, including cold rolling, hot rolling, cutting, bending and welding, can be made into a variety of shapes and sizes according to different needs.

Oxidation resistance

Stainless steel pipes have excellent oxidation resistance and remain resistant to oxidation even at extreme temperatures, making them suitable for piping applications in high temperature and open air environments.

Clean and easy to maintain

Stainless steel surface is smooth, easy to clean and maintain, very suitable for food processing, pharmaceutical and other industries with high hygiene requirements.

Product Paramenters

| Product Name | Stainless Steel Pipe |

| Steel grade | 200 series,300 series,400 series |

| Standard | ASTM A213,A312,ASTM A269,ASTM A778,ASTM A789,DIN 17456, DIN17457,DIN 17459,JIS G3459,JIS G3463,GOST9941,EN10216, BS3605, GB13296 |

| Surface | Polishing,annealing,pickling,bright |

| Technique | Hot rolled / cold rolled |

| stainless steel round pipe/tube | Wall thickness: 1mm-150mm(SCH10-XXS)Outer diameter: 6mm-2500mm (3/8"-100") |

| stainless steel square pipe/tube | Wall thickness: 1mm-150mm(SCH10-XXS)Outer diameter: 4mm*4mm-800mm*800mm |

| stainless steel rectangular pipe/tube | Wall thickness: 1mm-150mm(SCH10-XXS)Outer diameter: 4mm*4mm-800mm*800mm |

| Length | 4000mm,5800mm,6000mm,12000mm,or as required. |

| Application | Widely used in petroleum,foodstuff,chemical industry,construction, electric power,nuclear,energy,machinery,biotechnology,paper making,shipbuilding,boiler fields. Pipes also can be made according to the customer's required. |

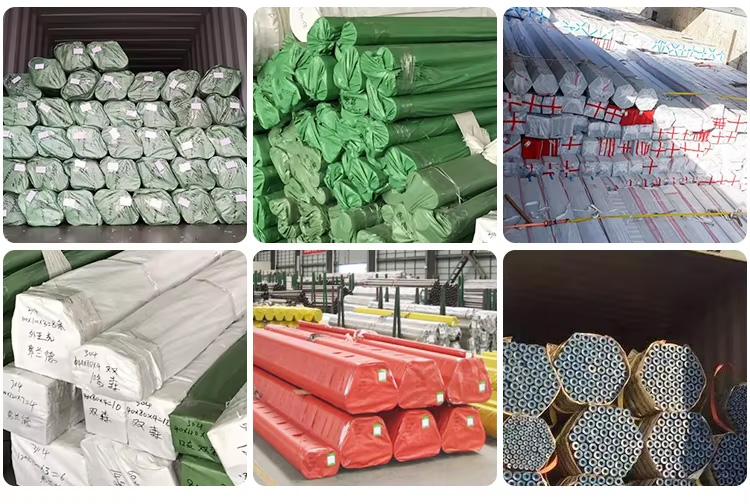

| Package | Standard export seaworthy package,or as required. |

Why Do We Use 316L Stainless Steel Strip For Continuous Spiral Finned Tubes?

316L stainless steel strip is an excellent choice when it comes to manufacture of stainless steel continuous spiral finned tubes.

The corrosion resistance of 316L stainless steel strip is better than 304 stainless steel strip, and it has good corrosion resistance in the production process industry. And 316L stainless steel strip is also resistant to the erosion of the ocean and corrosive industrial atmosphere.

In the intermittent application below 1600 degrees, 316 stainless steel strip has good oxidation resistance.

316L stainless steel strip has better resistance to carbide precipitation than normal 316 grade stainless steel.

Resistance to corrosion is an important feature when it comes to production of finned tubes. This explains why most people opt to use 316L stainless steel strip material in in continuous spiral finned tubes.

Company Information

Shandong Zechen Xinghua New Materials Co., Ltd.is a manufacture integrating production and trade, with more than 30 years of experience in high-quality production, providing one-stop service for global customers. The company specializes in the production and sales of Carbon steel pipe/bar/plate/coil/, Galvanized steel plate/coil, Stainless steel pipe/plate/coil/bar,Section steel(H-beams/T-beams/Chan-nel steels/Angle steels/Cross steels/Etc.) Rebar/Deformed steel bars,Aluminum plate/coil/pipe/bar,Copper/Brass/Bronze/Copper alloy and other metal products. Among them, our precision seamless steel pipes and welded steel pipes ofvarious diameters have reached the world's leading level, with an annual export volume of over 100,000 tons. At the same time, the company has a close cooperative relationship with Youfa Baosteel, TisCO,Shougang,Laigang,Shan Steel, Rizhao and other large domestic steel mills, with an annual sales volume of 500,000 tons. Products are exported to Europe, the Middle East, Southeast Asia, Australia, Latin America South Africa and other more than 60 countries and regions. We have won the recognition of customers with good reputation and good service. Since its establishment, the company has always adhered to the business philosophy of "Integrity is our fundamental principle;Quality is our highest pursuit;Service is our greatest commitment;", insisted on being yourself first, and then doing good deeds, aiming at customer satisfaction, reputation first, and focusing on providing customers with first-class products and meticulous and efficient services. Welcome customers to visit and negotiate. We look forward to establishing a long-term win-win cooperation with you!

Packing & Delivery

Certifications

Customer Photos

FAQ

Q:What are the common materials of stainless steel pipe?

Q:What is the corrosion resistance of stainless steel pipes?

Q:Can stainless steel tubes be used in high temperature environments?

Q:How is the processing performance of stainless steel pipe?

Q:What can be done on the surface of the stainless steel pipe?