-80px

-80px

-80px

-80px

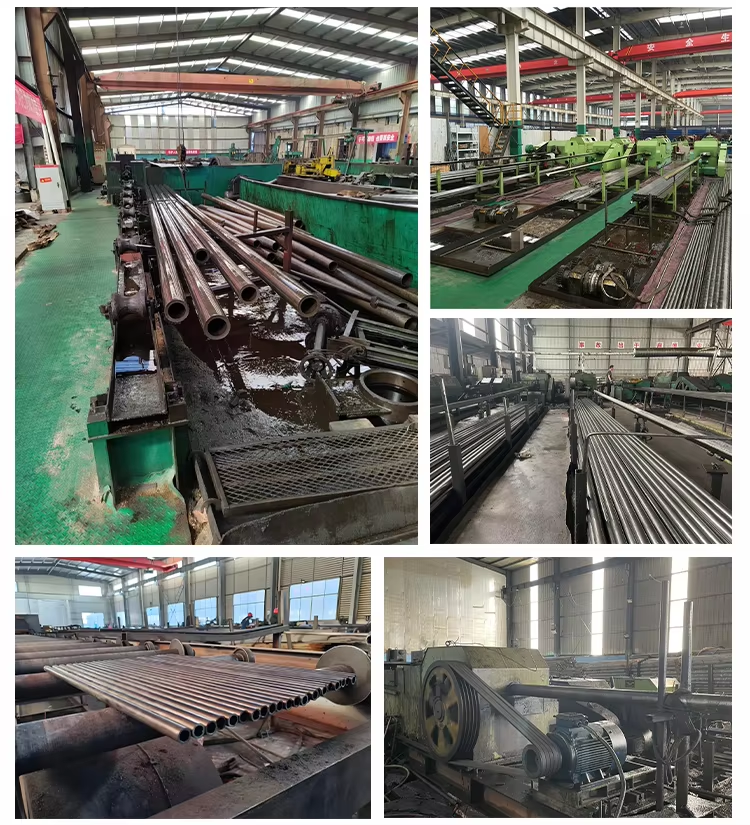

Production Process

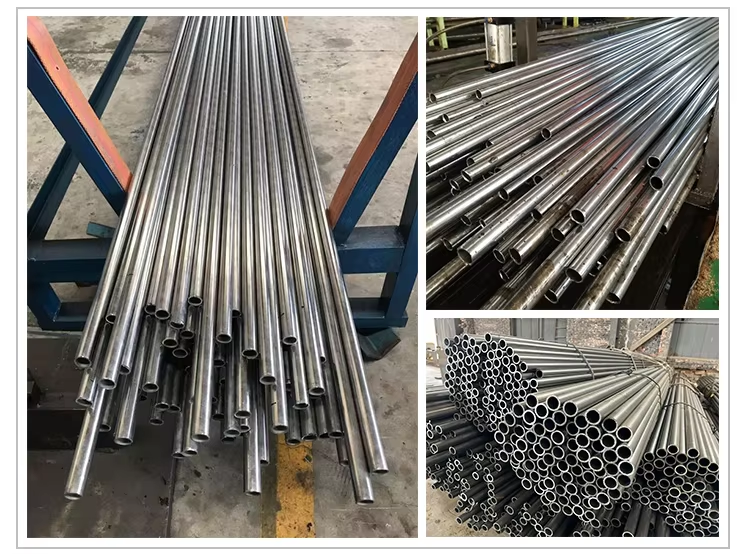

Product Description

ASTM A179, A192, and A210 precision seamless steel pipes are all seamless steel tube products under the standards of the American Society for Testing and Materials (ASTM). Each type exhibits distinct characteristics tailored to different application scenarios, as detailed below:

1. ASTM A179 Precision Seamless Pipe

Product Paramenters

| Product Name | Precision seamless steel pipe |

| Standard | GB/T 3639 DIN 2448, DIN1629,DIN1626,DIN2391,DIN2444,EN10025 etc. |

| Material | 10#,20#,45#,Q345,16Mn,15CrMo,30CrMo, 1Cr5Mo, 40Cr,42CrMo S235JR,S355JR, ST37,ST42,ST52,ST35 A106,A53, A179, 1020,T5, 42CrMo4,25CrMo4, 4130,4140 15XM etc. |

| Outer Diameter | 6-219mm |

| Wall Thickness | 1-20mm |

| Surface | Bright or oiled or black |

| Application | Automobile, motorcycle, electric car, petro chemical, electric power, vessel, aerospace, bearing, pneumatic components, medium and low pressure boiler, Bearing, hydraulic, mechanical processing ,ect. |

Packing & Delivery

Certifications