-80px

-80px

-80px

-80px

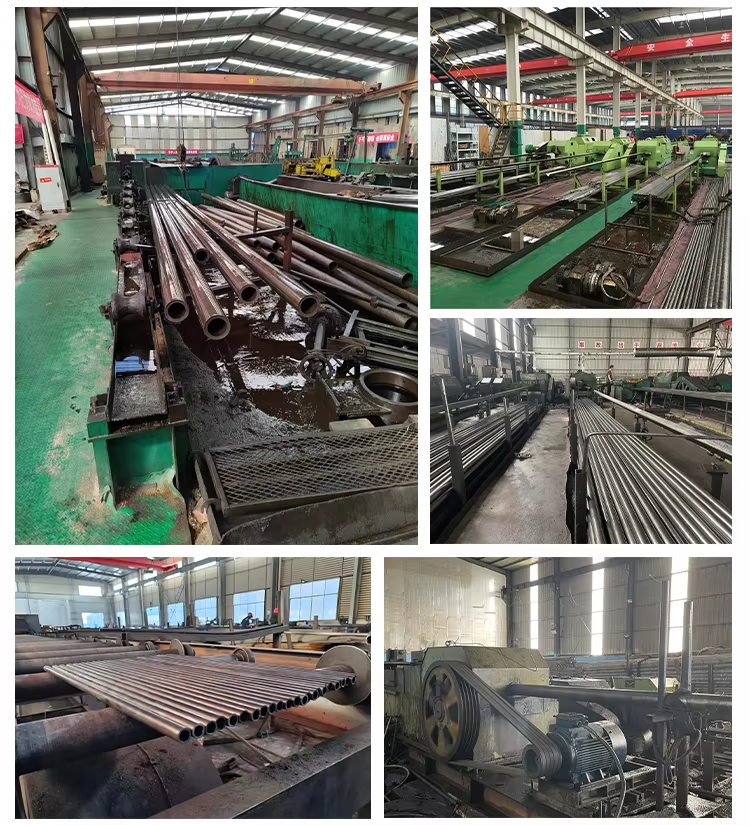

Production Process

Product Description

High dimensional accuracyPrecision steel tubes are manufactured by cold rolling or cold drawing processes, with relatively high dimensional accuracy, usually achieving a tolerance of ±0.05mm. High-precision dimensional control ensures the stability of the pipe during assembly and use, making it suitable for use in mechanical equipment that requires precise fit.

Smooth inner and outer surfacesThe inner and outer surfaces of precision steel tubes are smooth, reducing friction loss and improving the efficiency of fluid or gas flow inside the tubes. They are suitable for application scenarios such as hydraulic systems and pneumatic systems that require smooth inner walls.

Wear resistance and corrosion resistanceAfter surface treatment, precision steel tubes have excellent wear resistance and corrosion resistance, and can maintain a long service life in harsh environments. Common surface treatment methods include galvanizing, phosphating and oxidation treatment to enhance its durability in damp, acidic and alkaline environments.

Excellent mechanical propertiesPrecision steel tubes are typically made of high-quality carbon steel or low alloy steel. Through heat treatment (such as quenching and tempering), their tensile strength, yield strength and toughness are enhanced, enabling them to withstand high working pressure and mechanical stress, and making them suitable for use in high-intensity environments.

Product Paramenters

| Product Name | Precision seamless steel pipe |

| Standard | GB/T 3639 DIN 2448, DIN1629,DIN1626,DIN2391,DIN2444,EN10025 etc. |

| Material | 10#,20#,45#,Q345,16Mn,15CrMo,30CrMo, 1Cr5Mo, 40Cr,42CrMo S235JR,S355JR, ST37,ST42,ST52,ST35 A106,A53, A179, 1020,T5, 42CrMo4,25CrMo4, 4130,4140 15XM etc. |

| Outer Diameter | 6-219mm |

| Wall Thickness | 1-20mm |

| Surface | Bright or oiled or black |

| Application | Automobile, motorcycle, electric car, petro chemical, electric power, vessel, aerospace, bearing, pneumatic components, medium and low pressure boiler, Bearing, hydraulic, mechanical processing ,ect. |

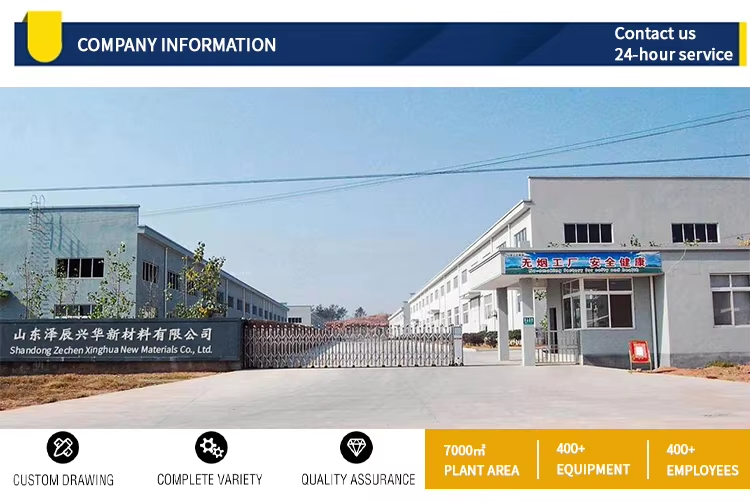

Shandong Zechen Xinghua New Materials Co., Ltd. is a manufacture integrating production and trade, with more than 30 years of experience in high-quality production, providing one-stop service for global customers. The company specializes in the production and sales of Carbon steel pipe/bar/plate/coil/, Galvanized steel plate/coil, Stainless steel pipe/plate/coil/bar,Section steel(H-beams/T-beams/Chan-nel steels/Angle steels/Cross steels/Etc.) Rebar/Deformed steel bars,Aluminum plate/coil/pipe/bar,Copper/Brass/Bronze/Copper alloy and other metal products.

Among them, our precision seamless steel pipes and welded steel pipes ofvarious diameters have reached the world's leading level, with an annual export volume of over 100,000 tons. At the same time, the company has a close cooperative relationship with Youfa Baosteel, TisCO,Shougang,Laigang,Shan Steel, Rizhao and other large domestic steel mills, with an annual sales volume of 500,000 tons. Products are exported to Europe, the Middle East, Southeast Asia, Australia, Latin America South Africa and other more than 60 countries and regions. We have won the recognition of customers with good reputation and good service.

Since its establishment, the company has always adhered to the business philosophy of "Integrity is our fundamental principle;Quality is our highest pursuit;Service is our greatest commitment;", insisted on being yourself first, and then doing good deeds, aiming at customer satisfaction, reputation first, and focusing on providing customers with first-class products and meticulous and efficient services. Welcome customers to visit and negotiate. We look forward to establishing a long-term win-win cooperation with you!

Packing & Delivery

Application

Automobile manufacturing: It is used for manufacturing components such as automotive drive shafts, bearings, and cylinders that require high precision and high strength.

Hydraulic system: Suitable for hydraulic cylinders and pneumatic cylinders. The inner wall is smooth to reduce friction loss, ensuring system sealing and efficiency.

Construction machinery: It is used for manufacturing precision mechanical components to ensure the stable operation of equipment in high-pressure environments.

Medical devices: The high precision and smoothness of precision steel tubes are suitable for use in medical equipment and instruments that require precise control.

Aerospace: It is used in equipment with high strength and lightweight requirements, such as aircraft transmission systems and precision parts.

Certifications

Customer Photos

FAQ

Q: What is the difference between precision steel pipe and ordinary steel pipe?

A: Precision steel pipe has high dimensional accuracy, smooth internal and external surfaces, no oxide layer, and more stable mechanical properties, which is suitable for occasions with high precision requirements. The accuracy and surface quality of ordinary steel pipes are low, and they are mainly used for general industrial purposes.

A:Precision steel pipes are usually produced by cold rolling or cold drawing processes. Cold-rolled steel pipe by rolling forming, higher dimensional accuracy; The cold-drawn steel pipe has higher mechanical properties by stretch forming.