-80px

-80px

-80px

-80px

Product Description

ASTM ERW (Electric Resistance Welding) Welded Steel Pipes are manufactured by rolling hot-rolled steel strips into a tubular shape via the ERW process, then fusing the pipe edges using resistive heat generated by electric current. Their core features center on "ASTM standard compliance, process advantages, and performance adaptability," detailed as follows:

Selling Point

1."Longitudinally Welded Steel Pipes Lsaw /ssaw Pipe" is a high-quality carbon steel product manufactured with ISO 9001

certification, perfect for building construction, boiler pipe, chemical fertilizer pipe, fluid pipe, gas pipe, oil pipeline, and

other structural applications.

2.Offered in a variety of specifications with Length options such as 1m to 12m, 12M, 6.4M, and 6m, this pipe line product is

manufactured with non-alloy AISI 5003 round-shaped steel and features a black bared surface.

Selling Point

3.Constructed using ERW and hot-rolled techniques, it comes with ±1% tolerance and is supplied in bundles with plastic bags and

strips. The product comes with various thickness options and Customs clearance advantages.

4.Providing excellent support in cutting and welding processing, the company offers shipping within 15-21 days and offers shop

primer and shot blasting as well as invoicing by actual weight.

5.A competitive advantage of "Longitudinally Welded Steel Pipes Lsaw" is its ability to withstand pressure and corrosion

resistance assured by the ISO 9001 certificate, with the ability to 'process special specifications based on drawings or samples.

Specification

| Product name | Welded Steel Pipe |

| Section Shape | Round/Square/Rectangular |

| Diameter | 15mm - 1400mm |

| 1Thickness | 1-20mm |

| Length | 5.8M,6M,12M |

| Tolerance | ±1% |

| Material | Carbon steel/Stainless steel |

| Technique | Hot rolled/Cold rolled |

| Welding type | ERW/HFW/SAW/SSAW/LSAW |

| Surface Treatment | Plain/Black/Galvanized/Oiled/Painted |

| Ends | Beveled Thread+Couplings |

| Processing Service | Welding, Punching, Cutting, Bending, Decoiling |

| Standard | GB/T3091-2001 , BS 1387-1985 , DIN EN10025 , EN10219 , JIS G3444:2004 , ASTM A53 SCH40/80/STD , BS- EN10255-2004 |

| Certificate | CE, API, ISO9001, BS, SNI |

| MOQ | 1 Ton |

| Packing | Standard Sea-worthy Package |

| Delivery Time | 7-30 days |

| Brand Name | ZCXH |

| Place of Origin | Shandong,China |

| Application | Fluid Pipe, Boiler Pipe, Drill Pipe, Hydraulic Pipe, Gas Pipe, OIL PIPE, Chemical Fertilizer Pipe, Structure Pipe |

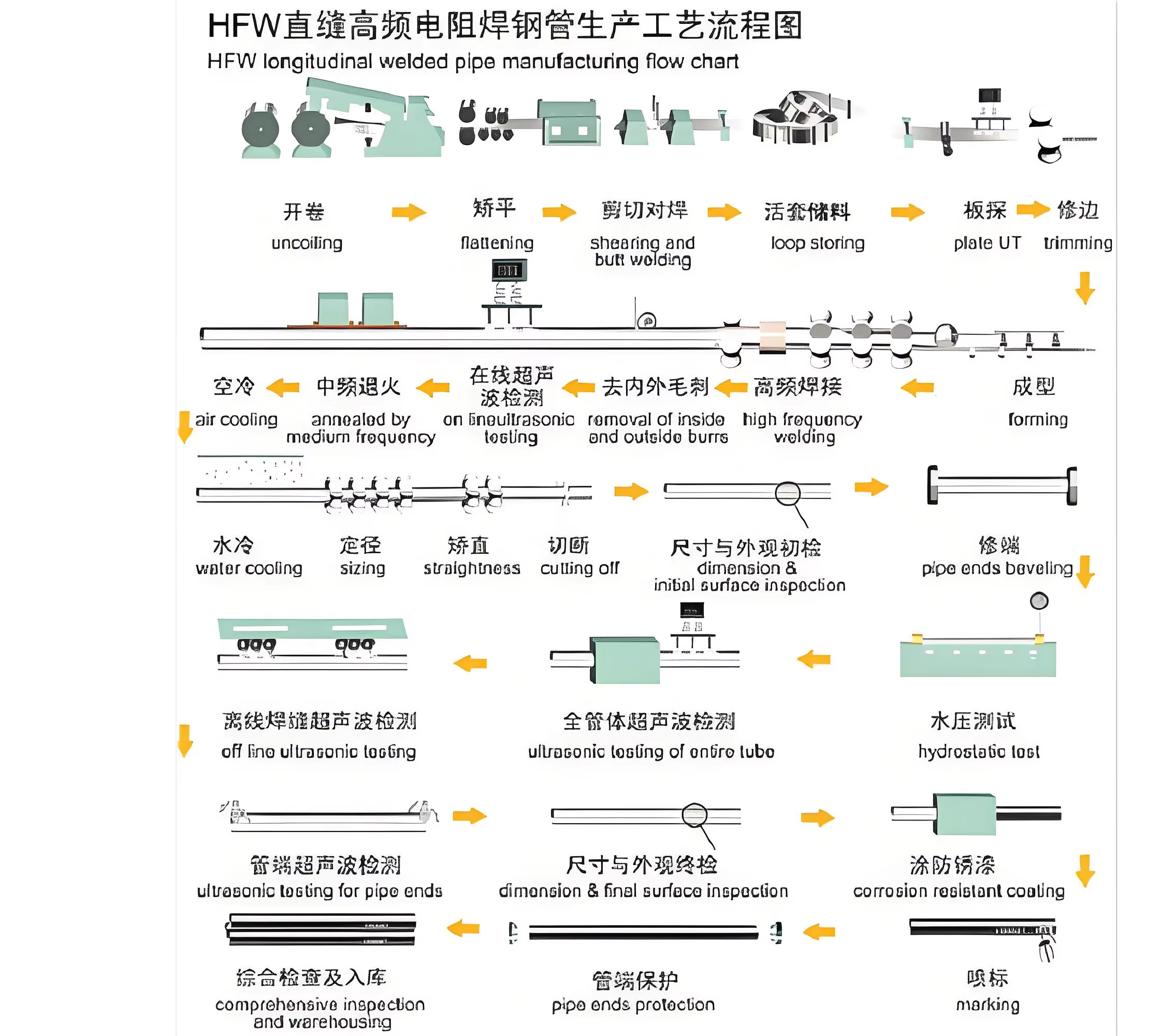

Manufacturing Technique

Products Application