-80px

-80px

-80px

-80px

Production Process

Product Description

High precision and smoothnessThe inner wall of the honing tube has undergone precise processing, with a low roughness and high smoothness on the inner surface. This can effectively reduce the piston friction in the hydraulic cylinder and pneumatic cylinder, extend the service life of the equipment, and improve work efficiency.

Strong dimensional stabilityHoning tubes have strict dimensional tolerance control and roundness accuracy, which makes them suitable for hydraulic and pneumatic systems with high precision requirements, ensuring the stable operation of the equipment.

Good wear resistanceThe inner wall of the honing tube has undergone special treatment, significantly enhancing its wear resistance. It can withstand high-frequency reciprocating motion and is particularly suitable for high-pressure and high-speed working conditions in hydraulic and pneumatic systems.

Superior sealing performanceThe smooth inner wall reduces the risk of leakage between the piston and the pipe wall, improves the sealing performance and efficiency of the system, and ensures the stability and reliability of the hydraulic or pneumatic system.

It has strong high-pressure resistanceHoning tubes can withstand high working pressure and maintain good stability and durability under high-pressure conditions, making them highly suitable for use in hydraulic and pneumatic equipment.

Product Paramenters

| Material | 16Mn, A53(A,B), Q235, Q345, Q195, Q215, St37, St42, St37-2, St35.4, St52.4, ST35 |

| Wall Thickness | 0.6MM~30MM |

| Outer Diameter | 21.3MM~660MM |

| Length | Length:Single random length/Double random length 5m-14m,5.8m,6m,10m-12m,12m or as customer's actual request |

| Standard | API 5L, ASTM A53-2007, ASTM A671-2006, ASTM A252-1998, ASTM A450-1996, ASME B36.10M-2004, ASTM A523-1996, BS 1387, BS EN10296, BS 6323, BS 6363, BS EN10219, GB/T 3091-2001, GB/T 13793-1992, GB/T9711 |

| Grade | 10#-45#, 16Mn, A53-A369, Q195-Q345, ST35-ST52 Grade A, Grade B, Grade C |

| Technique | ERW Welded Steel Pipe |

| Packing | Bundle, or with all kinds of colors PVC or as your requirements |

| Pipe Ends | Plain and Beveled,protected by plastic caps on both ends, grooved, threaded and coupling,etc. |

| Surface Treatment | 1. PVC,Black and color painting 2. Transparent oil,anti-rust oil 3. According to clients requirement |

| Certificates | API ISO9001-2008,SGS.BV |

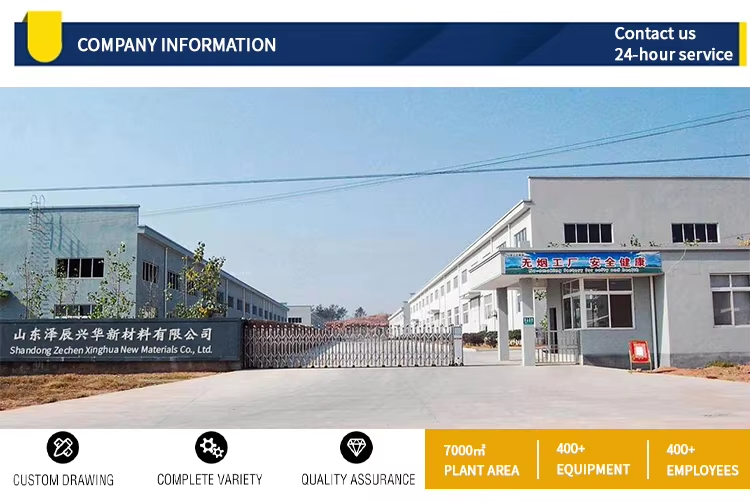

Shandong Zechen Xinghua New Materials Co., Ltd. is a manufacture integrating production and trade, with more than 30 years of experience in high-quality production, providing one-stop service for global customers. The company specializes in the production and sales of Carbon steel pipe/bar/plate/coil/, Galvanized steel plate/coil, Stainless steel pipe/plate/coil/bar,Section steel(H-beams/T-beams/Chan-nel steels/Angle steels/Cross steels/Etc.) Rebar/Deformed steel bars,Aluminum plate/coil/pipe/bar,Copper/Brass/Bronze/Copper alloy and other metal products. Among them, our precision seamless steel pipes and welded steel pipes ofvarious diameters have reached the world's leading level, with an annual export volume of over 100,000 tons. At the same time, the company has a close cooperative relationship with Youfa Baosteel, TisCO,Shougang,Laigang,Shan Steel, Rizhao and other large domestic steel mills, with an annual sales volume of 500,000 tons. Products are exported to Europe, the Middle East, Southeast Asia, Australia, Latin America South Africa and other more than 60 countries and regions. We have won the recognition of customers with good reputation and good service.

Since its establishment, the company has always adhered to the business philosophy of "Integrity is our fundamental principle;Quality is our highest pursuit;Service is our greatest commitment;", insisted on being yourself first, and then doing good deeds, aiming at customer satisfaction, reputation first, and focusing on providing customers with first-class products and meticulous and efficient services. Welcome customers to visit and negotiate. We look forward to establishing a long-term win-win cooperation with you!

Packing & Delivery

Application

Building structure: Supports, frames and scaffolding used for buildings.

Conveying pipeline: Suitable for long-distance transportation of fluids such as water, oil and natural gas.

Mechanical manufacturing: Widely applied in the production of mechanical structural components, equipment casings and support assemblies.

Agricultural facilities: irrigation systems, greenhouse supports and other agricultural facilities.

Municipal engineering: drainage pipes, bridge guardrails, etc.

Certifications

Customer Photos

FAQ

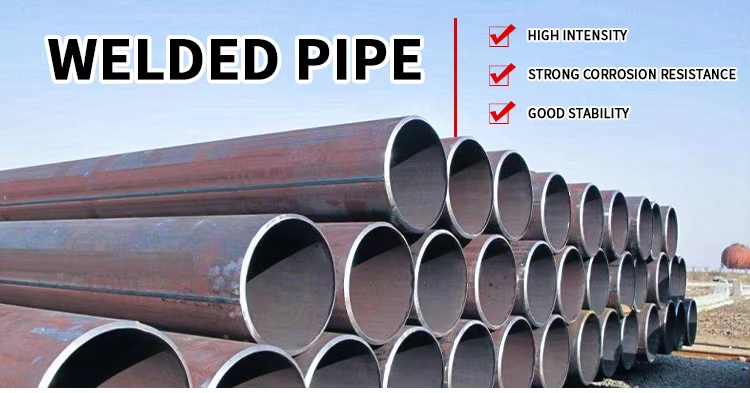

Q:What are the common types of welded steel pipes?

A:Common types include straight seam welded steel pipes (ERW steel pipes), spiral welded steel pipes and arc welded steel pipes.

A:Welded steel pipes are widely used for transporting fluids such as water, oil, natural gas and steam, and are also applied in construction, Bridges, roads and mechanical structures, etc.

A:Welded steel pipes are usually made of carbon steel, stainless steel, low alloy steel and other materials, and different materials are selected according to different uses.

A:Welded steel pipes are made by rolling steel plates or steel strips and welding them into pipes through processes such as high-frequency resistance welding or arc welding. Then, quality control is carried out through finishing and inspection.