-80px

-80px

-80px

-80px

Company Profile

Products Description

Made of high-grade low carbon steel (e.g., Q235 or 45# steel, compliant with building material standards) with excellent tensile, yield, and impact resistance.

The mechanical properties of the coupler match or exceed those of the connected low carbon steel bars, ensuring the overall load-bearing capacity of the reinforced concrete structure is not compromised—even under dynamic or heavy loads (e.g., seismic forces, structural dead weight).

Features precision-machined parallel threads (thread pitch, diameter, and tooth profile strictly adhere to industry standards like GB/T 1499.3 or ASTM A615). The thread fit is tight and uniform, eliminating gaps that could cause connection looseness.

Enables "full-thread engagement" between the coupler and steel bars: when installed correctly, the bar threads fully penetrate the coupler, distributing stress evenly across the connection and avoiding localized stress concentration (a common cause of connection failure).

No need for on-site welding or grouting—only requires matching pre-threaded steel bars to be screwed into the coupler (can be operated with standard hand tools or electric wrenches).

The parallel thread structure allows for quick alignment of steel bars, reducing installation time by 30%–50% compared to traditional welding methods. It also minimizes skill requirements for operators, ensuring consistent installation quality across projects.

Effectively resists corrosion from moisture, concrete alkaline substances, or outdoor environmental factors (e.g., rain, humidity), preventing rust-induced degradation of the connection over long-term use and extending the service life of the reinforced structure.

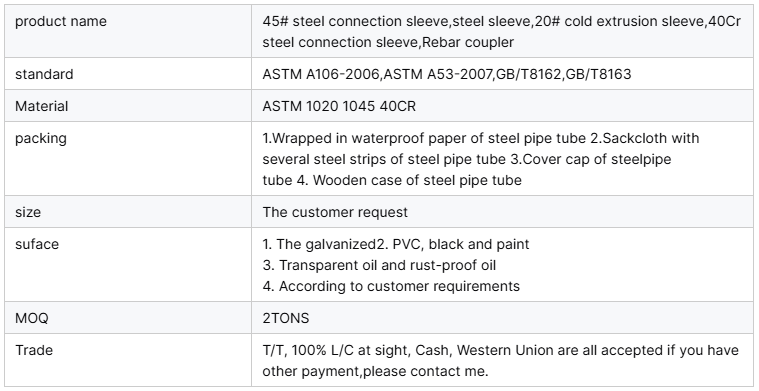

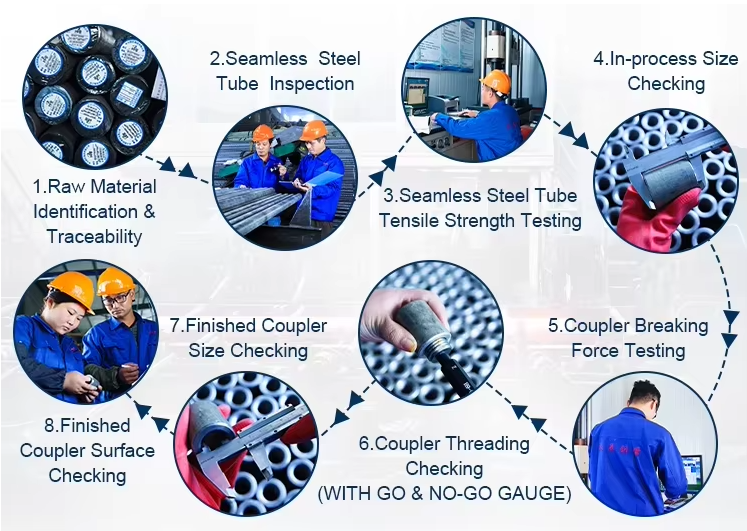

All components (coupler body, internal threads, and auxiliary parts) undergo strict dimensional inspection (via precision measuring tools like thread gauges or calipers) to ensure uniform specifications.

Details Images

Recommend Products

Product packaging

FAQ

Q1:Can you send samples?