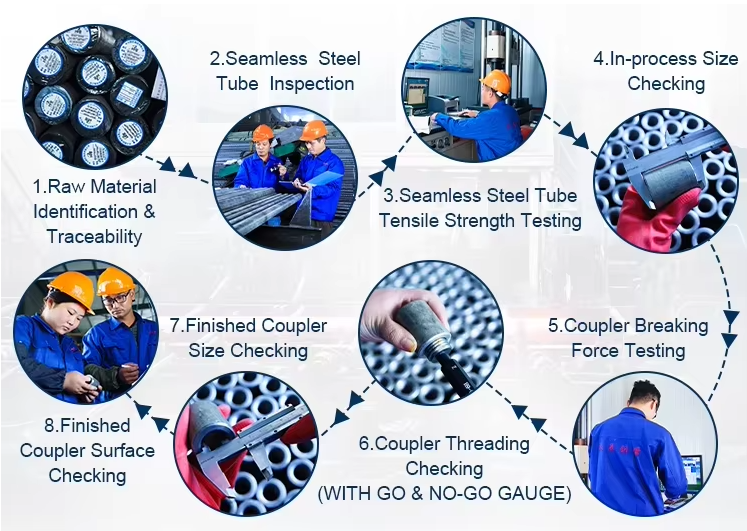

Q2.How can we guarantee quality?

A:Always a pre-production sample before mass production;Always final Inspection before

shipment.

Q3. Is your company a trading company or a manufacturer?

A: There is no doubt that we are a professional material manufacturer in China. Carry out one week business internship year. Our factory, workshop and warehouse are located in liaocheng City,shandong Province, China. If possible, we would like to invite all customers to visit our company and factory

Q4:What ports of shipment are there?

A:Under normal circumstances, we ship from qingda, dalian lianyungang ports, you can specify other ports according to your needs.

Q5:What about product prices information?

A:Prices various according to periodic price changes of raw materials.

Q6.Do you provide custom made Products service?

A: Yes,if you have your own design , we can produce according to your specification and drawing.

Q7:How long does your delivery time take?

A:In general, our delivery time is within 7-15 days, and may be longer if the quantity is extremely large or special circumstances occur.

Q8:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q9: How many countries have you visited?

A: We have exported to the Middle East, Europe, America, Southeast Asia and other regions, and have signed long-term cooperation agreements with dozens of companies and regional agents. We have rich export experience, and we are familiar with different market demands and can help ustomers avoid a lot of trouble.