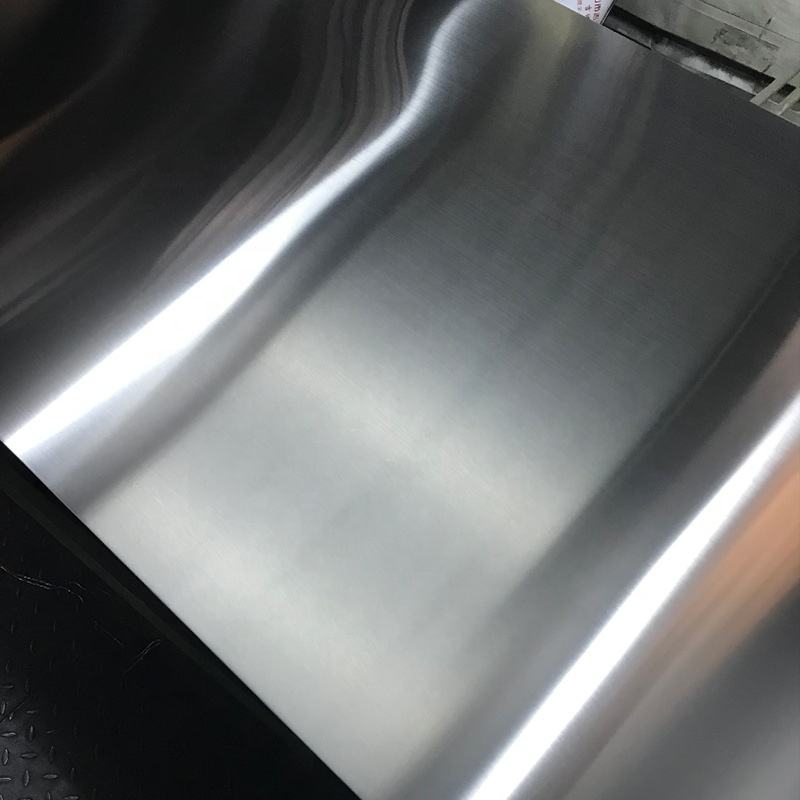

Typically made of high-performance stainless steel grades (primarily SUS304 or SUS316), it inherits the material’s inherent resistance to wear, corrosion, and environmental aging, ensuring strong long-term reliability:

Corrosion & Rust Resistance: The chromium oxide passive film on the stainless steel surface effectively isolates moisture, rainwater, road salt (for automotive use), seawater (for marine use), and industrial fumes. Unlike carbon steel roll bars (which require frequent painting for rust prevention), stainless steel versions remain rust-free for 15–30 years even in harsh environments such as coastal areas or off-road muddy conditions.

Abrasion & Impact Resistance: With high tensile strength (≥515 MPa for SUS304) and excellent hardness, the material can withstand scratches from rocks, debris, or daily use without deformation or surface damage. It maintains structural integrity even after repeated minor impacts.

Weather & UV Resistance: When exposed to sunlight, extreme temperatures (-40°C to 300°C), or humid environments for a long time, it is not prone to fading, cracking, or brittleness—suitable for scenarios such as outdoor parked vehicles and marine equipment.

As a safety-focused component (especially in automotive scenarios), it enhances load-bearing and impact resistance through structural design to protect personnel or equipment:

Anti-Roll & Collision Protection: In the automotive field (e.g., pickup trucks, off-road vehicles), it acts as a "protective cage" for the vehicle cab. When the vehicle rolls over or is hit, its high yield strength (≥205 MPa for SUS304) and rigidity prevent the cab from collapsing, reducing the risk of injury to occupants.

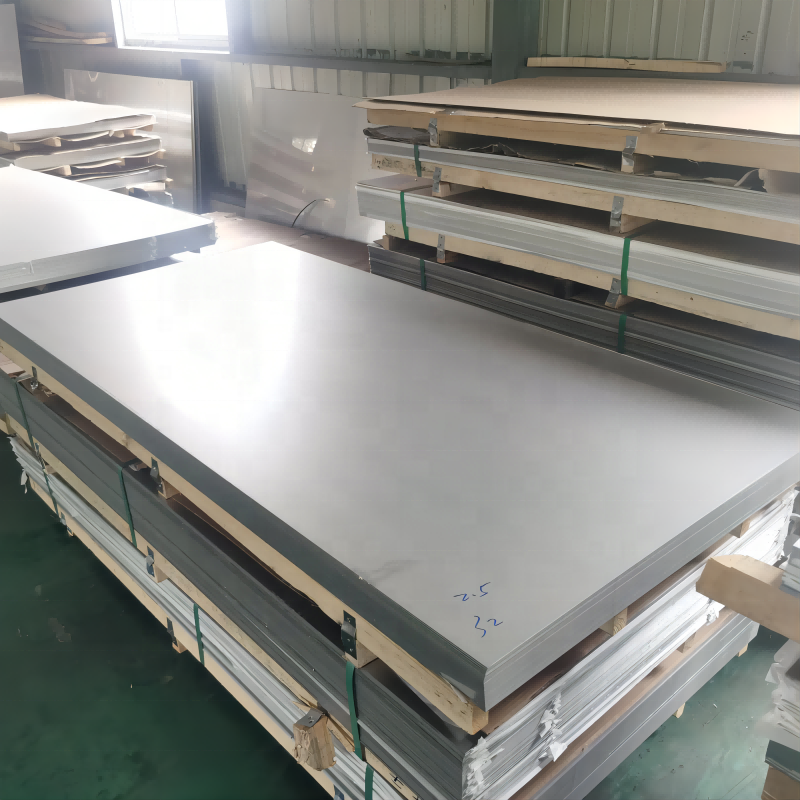

Strong Load-Bearing Capacity: Mostly adopting tubular or solid stainless steel structures (common tubular thickness: 1.5–3 mm), it can bear heavy loads—such as supporting roof racks, spare tires, or cargo (load capacity up to 50–200 kg depending on specifications)—without bending.

Shock Absorption: The material has moderate toughness (elongation ≥40% for SUS304), which can absorb part of the impact energy during collisions and reduce the transmission of impact force to the vehicle body or personnel.

Its design aligns with the needs of different industries, featuring strong environmental and functional adaptability:

Automotive Applications: Used in off-road vehicles, pickup trucks, and racing cars. It can be customized into single-bar, double-bar, or cage structures; some versions are integrated with LED light mounts or spare tire carriers to enhance practicality.

Marine Applications: Installed on boats, yachts, or offshore platforms as handrails, guardrails, or anti-collision bars. Its resistance to seawater corrosion eliminates the need for frequent maintenance caused by salt spray.

Industrial Applications: Used in warehouses, workshops, or heavy machinery as safety barriers (to prevent equipment collisions) or load-bearing supports. It adapts to dusty, humid, or chemical-rich industrial environments.