-80px

-80px

-80px

-80px

Product Description

Dual Material Advantages: Combines the corrosion resistance, oxidation resistance, and hygiene of stainless steel (cladding layer) with the high strength, rigidity, and cost-effectiveness of carbon steel or alloy steel (base layer), achieving optimal performance balance.

Strong Metallurgical Bonding: The interface between the two metals forms a tight metallurgical bond (via processes like explosive welding or hot rolling), ensuring no delamination during fabrication (cutting, welding, bending) or long-term use.

Cost Efficiency: Reduces reliance on expensive pure stainless steel by using a carbon steel base, significantly lowering material costs while maintaining critical corrosion resistance for specific applications.

Versatile Customization: Cladding can be tailored to different stainless steel grades (e.g., 304, 316) for varying corrosion needs, paired with base materials (mild steel, low-alloy steel) to match strength requirements, adapting to diverse industrial environments.

Easy Fabrication: Handles like a single metal plate in processing—compatible with standard welding, cutting, and forming techniques, simplifying manufacturing workflows.

Wide Application Suitability: Ideal for pressure vessels, chemical tanks, marine structures, and food processing equipment, where both corrosion resistance and structural strength are essential.

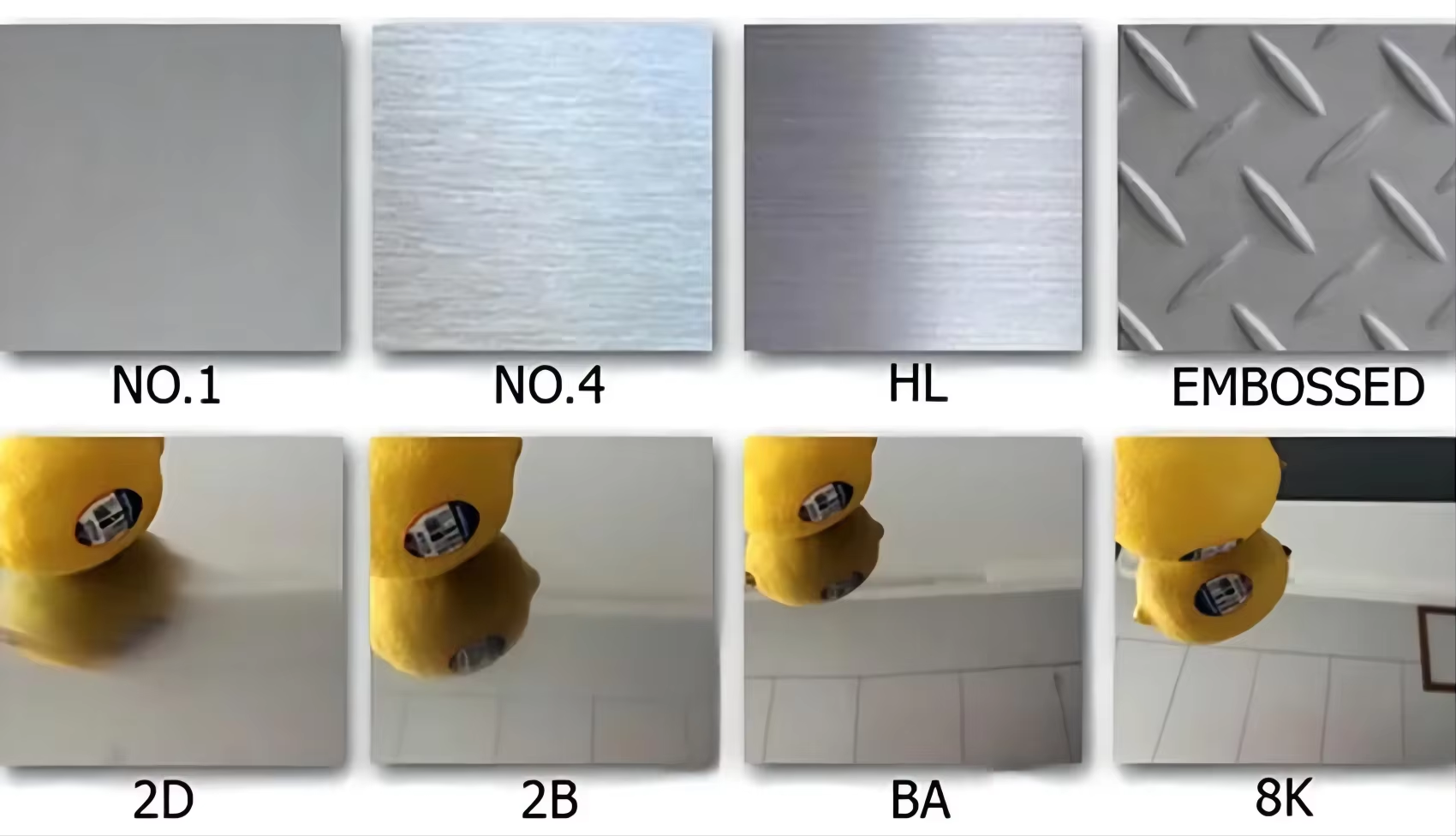

Product Surface

| Surface finish | Characteristics & Application |

| NO.1 | Hot-rolled surface,annealed and pickled,can be used as cold-rolling material,industial tanks and chem i cal devices. |

| 2D | Cold-rolled, an nealed and pick led with out skinpassing the dull prod ucts can be used as auto mo bile parts, building materrials and pipings. |

| 2B | The surface brightness and flatness of NO.2B is better than NO.2D. Then through a special surfacetreament to improve its mechamical properties, N02B could nearly satisfy com pre hen sive uses. |

| NO.3 | Polished with abra sive belt of grit #100#120,have bet ter bright ness with dis con tin u ous coarse stria, used as in ner and exter nal or na ments for building, elec tri cal ap pli anc es and kitchen uten sils etc. |

| NO.4 | Polished with abrasive belt of grit #150#180, have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtud buildinginner and external ornaments electrical appliances, kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-320 on the No.4 finish and has continuous streaks, mainly used as building ornaments,elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright an nealed and skin passed, the prod uct has ex cel lent bright ness and good re flex iv i ty like mirror, used for lectrical appliances, mirror, kitch en apparatus, or na ment ma te ri als etc. |

Specification

| item | value |

| Grade | 304N, 310S, 316Ti, 316L, 316, L4, 321,04, 314, 430, 304, 409L, 304L, 301L, S30815, 301, 304N, 310S, S32305, 410, 204C3, 316Ti, 316L, 441, 316, L4, 420J1, 321, 410L, 436L, 410S, 430, 304, 204C2, 445 |

| Standard | DIN |

| Tolerance | ±1% |

| Surface Finish | 2B |

| Place of Origin | Shandong,China |

| Delivery Time | 15-21 days |

| Thickness | 0.3mm-20mm |

| Length | 3000mm 6000mm or as required |

| Brand Name | ZCXH |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting |

| Product name | 304 Stainless Steel Round Bar |

| Technique | Cold Rolled Hot Rolled |

| Shape | Flat Steel Plate |

| Keyword | Staninless Steel Round |

| Surface | NO.1/2B/BA/NO.4/8K/SB/HL/Embosses/Etched/Decorate Stainless Steel |

| Material | Bar 201/202/309/309S/310/310S/304/304L/316/316L/316Ti/321 |

| MOQ | 5 Tons |

| Packing | Standard Sea-worthy Packing |

| Payment term | 30%T/T Advance + 70% Balance |

| Sample | Provided |

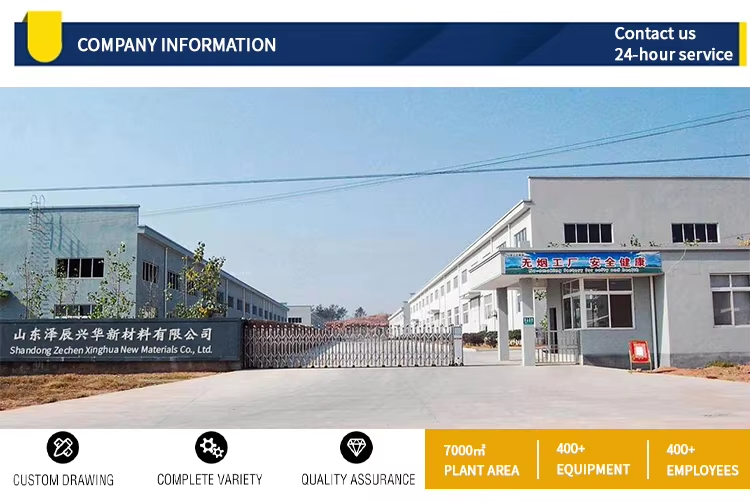

Shandong Zechen Xinghua New Materials Co., Ltd. is a manufacture integrating production and trade, with more than 30 years of experience in high-quality production, providing one-stop service for global customers. The company specializes in the production and sales of Carbon steel pipe/bar/plate/coil/, Galvanized steel plate/coil, Stainless steel pipe/plate/coil/bar,Section steel(H-beams/T-beams/Chan-nel steels/Angle steels/Cross steels/Etc.) Rebar/Deformed steel bars,Aluminum plate/coil/pipe/bar,Copper/Brass/Bronze/Copper alloy and other metal products. Among them, our precision seamless steel pipes and welded steel pipes ofvarious diameters have reached the world's leading level, with an annual export volume of over 100,000 tons. At the same time, the company has a close cooperative relationship with Youfa Baosteel, TisCO,Shougang,Laigang,Shan Steel, Rizhao and other large domestic steel mills, with an annual sales volume of 500,000 tons. Products are exported to Europe, the Middle East, Southeast Asia, Australia, Latin America South Africa and other more than 60 countries and regions. We have won the recognition of customers with good reputation and good service.

Since its establishment, the company has always adhered to the business philosophy of "Integrity is our fundamental principle;Quality is our highest pursuit;Service is our greatest commitment;", insisted on being yourself first, and then doing good deeds, aiming at customer satisfaction, reputation first, and focusing on providing customers with first-class products and meticulous and efficient services. Welcome customers to visit and negotiate. We look forward to establishing a long-term win-win cooperation with you!

Products Application

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Certifications

Customer Photos

FAQ

1. who are we?

We are based in Shandong Province, China, start from 2020,sell to Domestic Market(59.00%),Africa(9.00%),Mid East(8.00%),South America(6.00%),North America(3.00%),Southeast Asia(3.00%),South Asia(3.00%),Eastern Asia(2.00%),Central America(2.00%),Eastern Europe(1.00%),Oceania(1.00%),Western Europe(1.00%),Northern Europe(1.00%),Southern Europe(1.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Steel Pipes/Tubes,Steel Plates/Sheet,Steel Coils/Strip,Copper Plate/Sheet/Strip/Coil,Aluminum Plate/Sheet/Strip/Coil

4. why should you buy from us not from other suppliers?

Shandong Zechen Xinghua New Materials Co., Ltd. is a manufacture integrating production and trade, with more than 30 years of experience in high-quality production, providing one-stop service for global customers. The company specializes in the production

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,CPT,DDP,DDU;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian