-80px

-80px

-80px

-80px

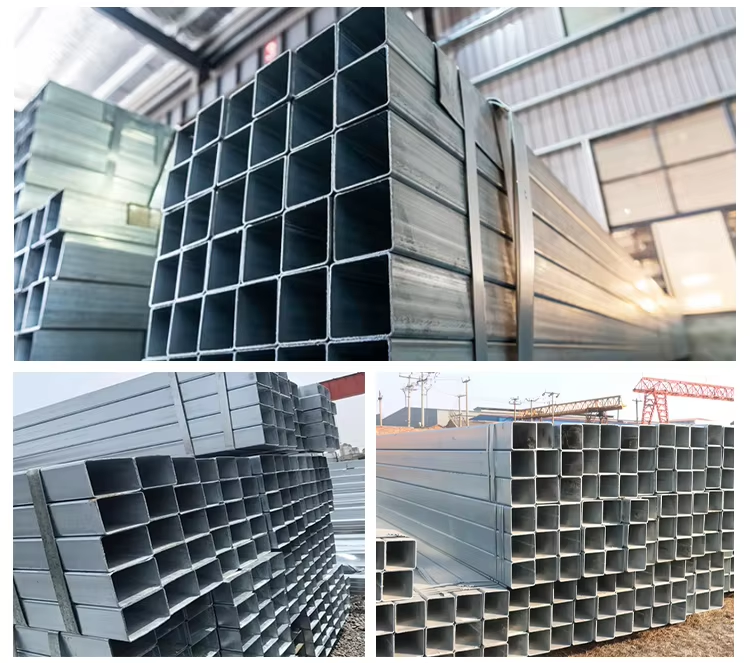

Product Description

Rectangular Galvanized Tubes, Galvanized Square Tubes, and Seamless Square Iron Tubes are three common structural and fluid-transmission components in construction, machinery, and municipal engineering. Each type combines unique structural forms (rectangular/square) with material/process advantages (galvanization/seamless), and their core features are detailed as follows:

Company Information

Packing & Delivery

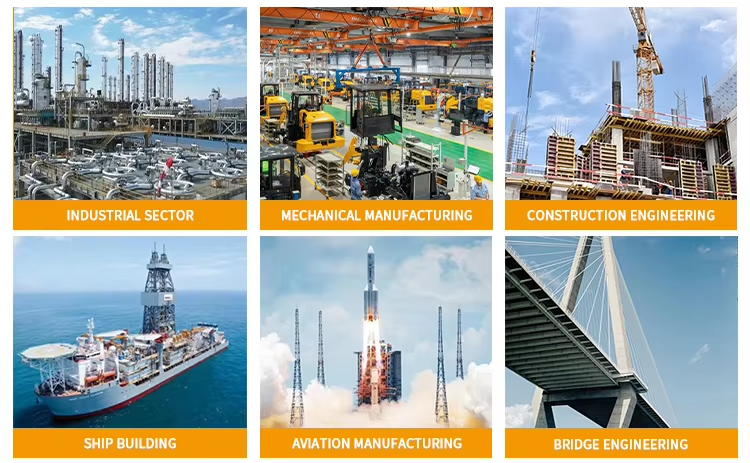

Application

Structural engineering (buildings, bridges, towers)

Machinery manufacturing

Steel frameworks and fabrication

Transportation equipment

Furniture and architectural projects

Fencing, gates, and support columns

Certifications