-80px

-80px

-80px

-80px

Product Description

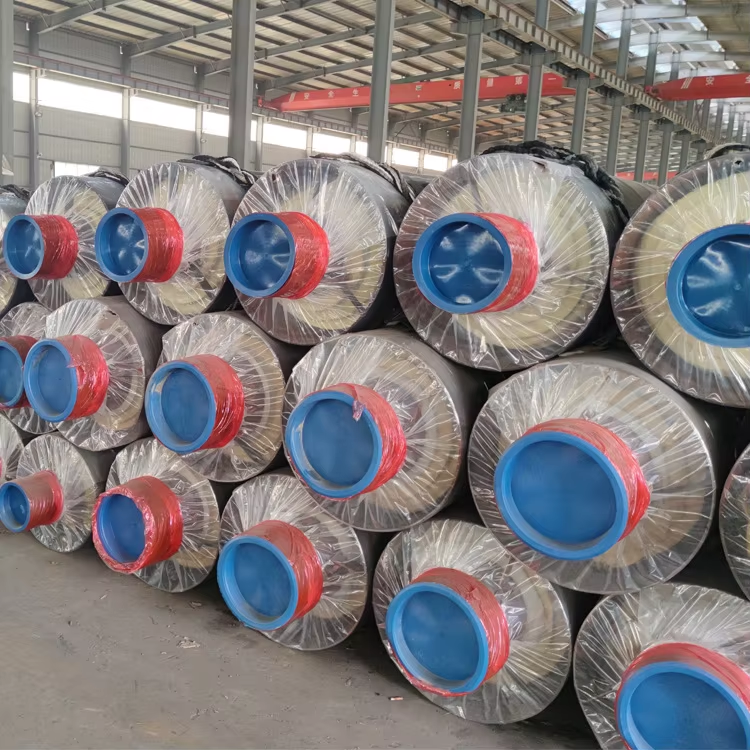

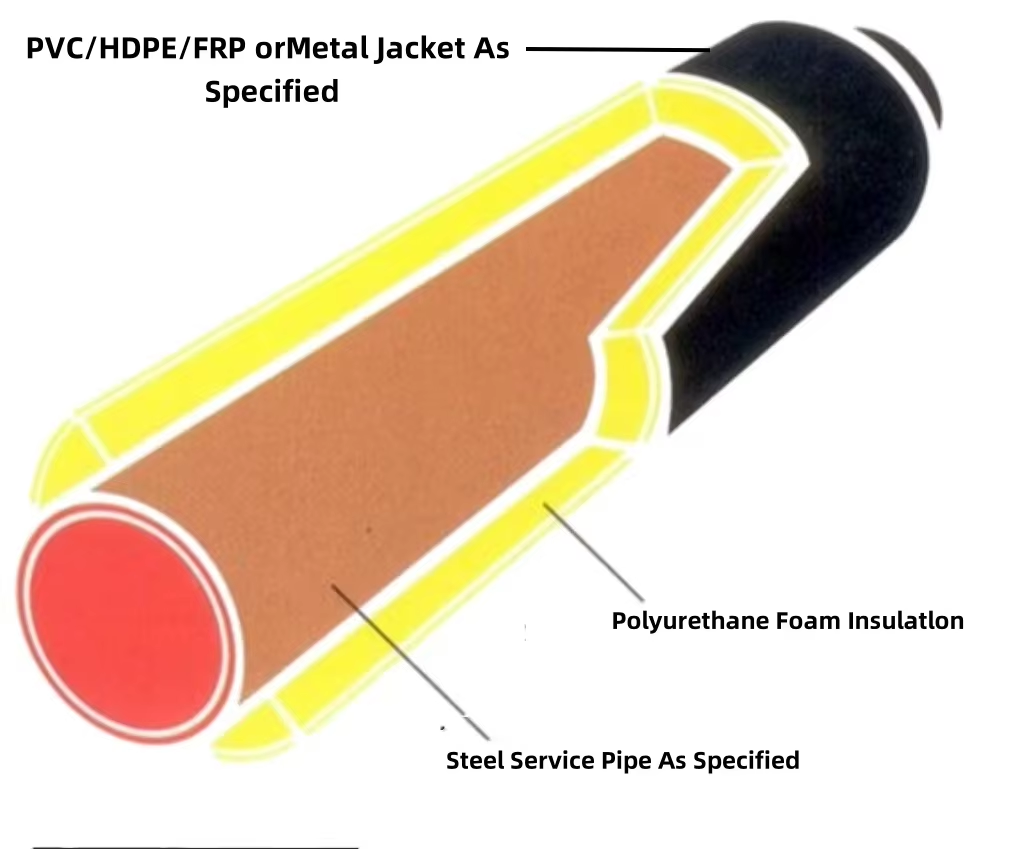

Pre Insulated Polyurethane Foam Insulation Steel Pipe (short for "PU pre-insulated steel pipe") is a composite pipe structure integrating a steel pipe (carrier layer), polyurethane foam (insulation layer), and outer protective layer (e.g., HDPE pipe). It is widely used in thermal fluid transmission (e.g., hot water, steam, district heating) and low-temperature medium transportation. Its core product features are as follows:

Specification

| item | value |

| Section Shape | ROUND |

| Surface Treatment | Hot Rolled |

| Oiled or Non-oiled | Non-oiled |

| Place of Origin | Shandong,China |

| Alloy Or Not | Non-Alloy |

| Standard | ASTM |

| Technique | SAW |

| Grade | Q235/Q235B/Q345/Q345B |

| Delivery Time | 15-21 days |

| Tolerance | ±1% |

| Invoicing | by actual weight |

| Brand Name | ZCXH |

| Application | Boiler Pipe, Drill Pipe, Hydraulic Pipe, Gas Pipe, OIL PIPE, Chemical Fertilizer Pipe, Other, Structure Pipe, Fluid Pipe |

| Special Pipe | API Pipe, Other, Thick Wall Pipe, EMT Pipe |

| Thickness | 2.1mm--60mm |

| Length | 12M, 6m, 6.4M |

| Certificate | API, ce, Bsi, BIS, ISO9001 |

| Processing Service | Welding, Cutting, Punching, Bending, Decoiling |

| Product name | Pre-insulation steel pipe |

| Keyword | welded round steel pipes |

| MOQ | 5TON |

| Payment term | 30%TT Advance + 70% Balance |

| Sample | Provide |

| Material | Q195-Q345 Q195/Q215/Q235/Q345/10#/20# |

| Shape | Round Pipe Tube |

| Length | 1-12m |

| Packing | Standard Seaworthy Packing |

| Technique | Hot Rollled |

Our Products

Applications