-80px

-80px

-80px

-80px

Overview

Product Description

Thin Wall Small Diameter Precision Tubes are specialized tubular components engineered for applications where minimal weight, compact size, and ultra-tight precision are critical. Defined by their narrow outer diameter (typically ≤ 20mm) and thin wall thickness (often ≤ 2mm, with wall-to-diameter ratios as low as 0.05), these tubes combine dimensional accuracy with structural efficiency—making them indispensable for miniaturized, high-performance systems across industries.

Small Diameter: With OD as narrow as 0.3mm, these tubes fit into confined spaces (e.g., micro-electronic devices, medical catheters) where standard tubes cannot be installed.

Thin Wall Construction: Minimizes material usage while maintaining structural integrity, reducing overall weight by 30–50% compared to standard thick-wall tubes. This is critical for weight-sensitive applications (e.g., aerospace components, portable medical devices).

Tight Tolerances: Controlled via CNC cold drawing, precision rolling, or laser machining, ensuring consistent OD/ID/wall thickness across the entire tube length. Even minor deviations (e.g., ±0.005mm) are eliminated—critical for applications like fluidic channels (where flow rate depends on ID) or mechanical fits (where misalignment causes failure).

High Strength-to-Weight Ratio: Despite thin walls, the use of high-grade materials (e.g., 316L stainless steel, titanium alloy) and precision manufacturing (e.g., cold working to refine grain structure) delivers tensile strength up to 800MPa—enough to withstand pressure, vibration, or cyclic stress (e.g., in automotive engine components).

Controlled Flexibility: Thin walls enable moderate bending (without cracking) for applications requiring contouring (e.g., medical catheters that navigate body cavities, flexible sensor probes).

Product Display

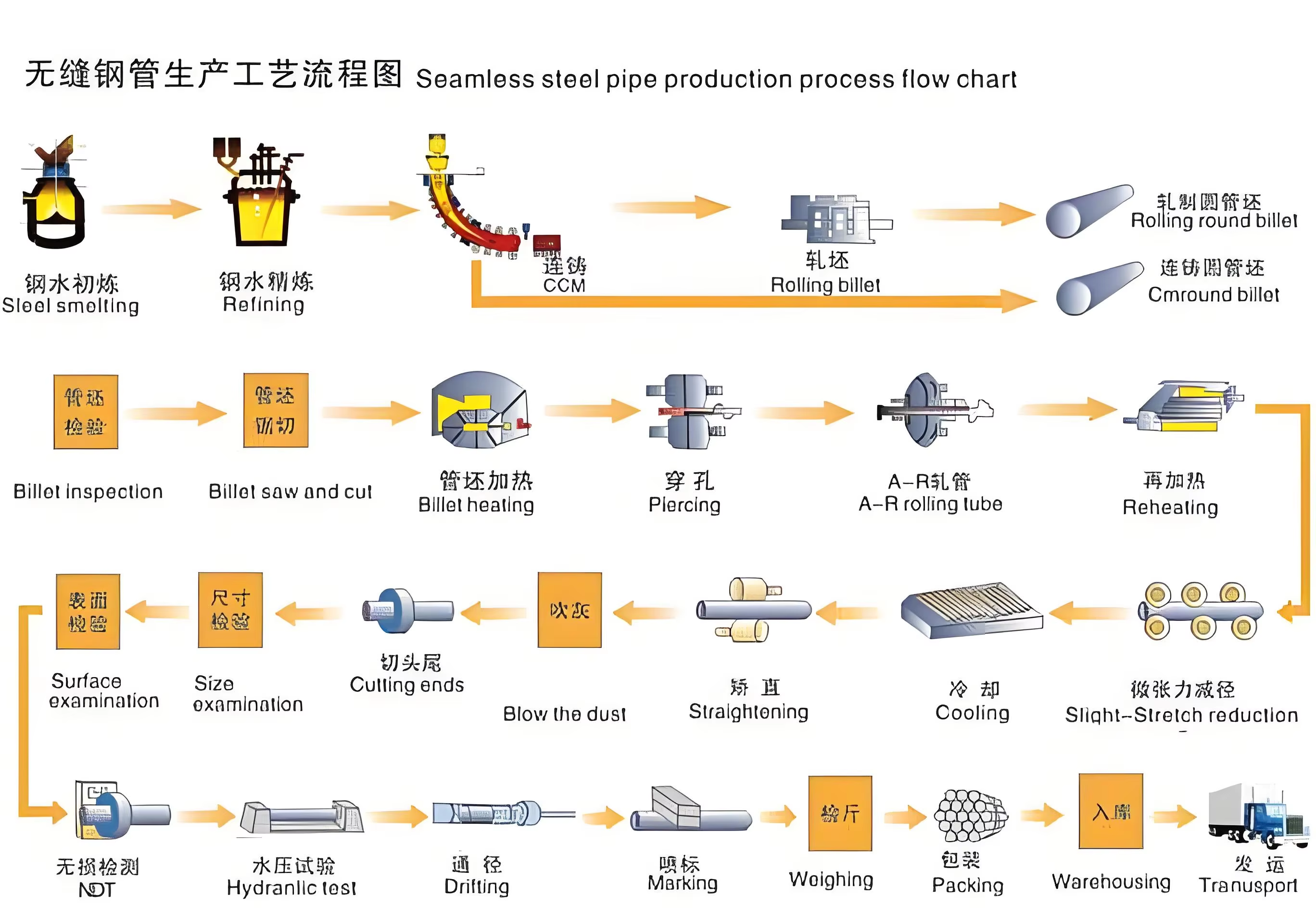

Manufacturing Technique

OurProducts

Products Application